- Joined

- Aug 18, 2016

ROG Paragon Build Log

by Chas Burkhart

by Chas Burkhart

Welcome to my project announcement of my case mod/ build log of the ROG Paragon! I would like to thank Republic of Gamers, In Win and EKWB for making this happen. The case mod/ build will represent some of the finest names in the computer industry. Above you will find my base concept of the build.

Paragon means, viewed as a model of excellence. This is why I chose Paragon as a name for this build. To me Republic of Gamers motherboards are just that, a model of excellence. Like In Win cases are for their cases and EKWB are for their cooling.

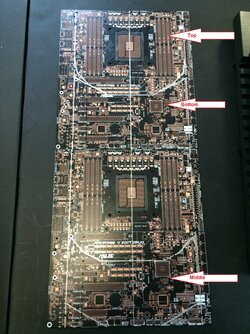

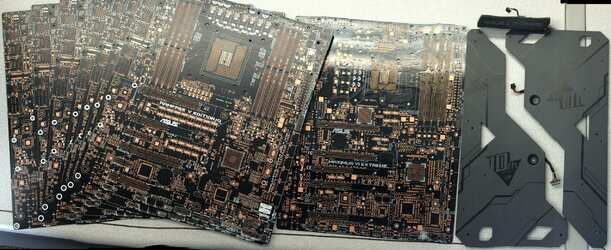

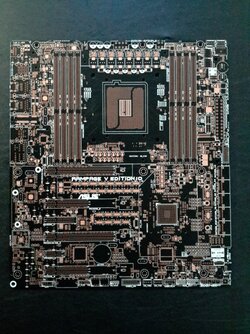

The case mod will be with the beautiful In Win 509 ROG Certified. The In Win 509 will be modded using Republic of Gamers Rampage V Edition 10 PCB blanks along with a couple other ROG parts. Next I will be cutting the pattern using a Craftsman Scroll Saw and Dremel cutting wheels.

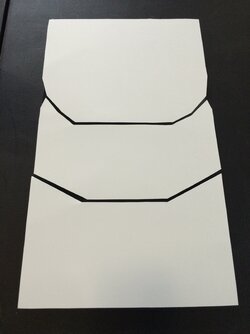

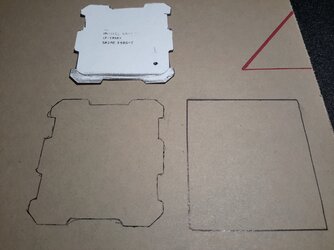

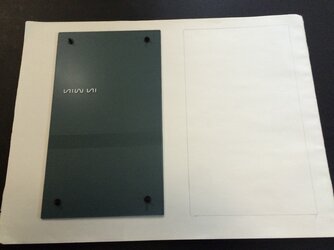

The case front will be backed with smoked cast acrylic to match the smoked glass of the 509 and maintain that menacing look. I used card stock to trace the 509 front glass and sketch the Strix GPU pattern.

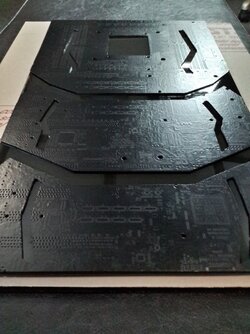

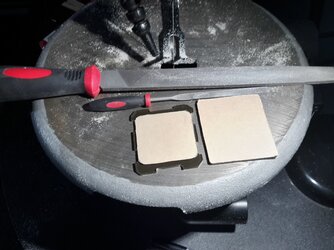

After the templates were cut I used a metallic silver Sharpie to trace the templates onto the PCB blanks. I made sure to utilize as much of the PCB as I could.

I will be using the Strix LED pattern on the front, side and top of the case by cutting the pattern into the PCB blanks. Above you can see the basic front PCB pattern that will be on top of the smoked acrylic for the front glass. I wanted to give it that Strix GPU look on the front of the case as well as retaining the R5E10 PCB. I will be placing the LED pattern once I have the basic outer pattern cut.

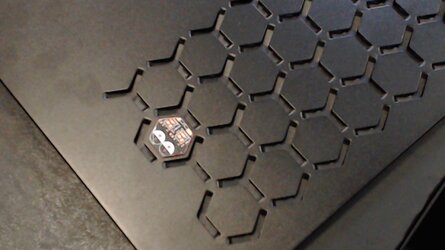

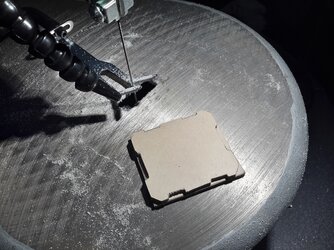

I have also started to cut the hexagons from the PCB to pattern over the side vents of the 509. I thought this was a really good design on the case and wanted to accent it. I used a Craftsman Scroll Saw to cut the above hexagon and made sure to leave a small lip of the original hexagon to show. I rounded the edges using a Dremel and standard sanding drum. See the video above for the first cut hexagon.

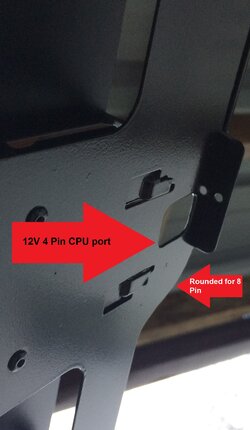

I began by disassembling the In Win 509, isn’t she sexy with nothing on? This was a very easy process and took roughly an hour while taking pics along the way. I will be attempting to also remove the red center support for some internal modding then place it back into the build. It is held in by small rivets and will require nuts and bolts to be fitted back in place.

I am also using the EKWB CoolStream PE 360 along with 6 120mm static pressure RGB fans in a push-pull configuration and a EKWB EK-XRES Revo D5 PWM. I will be installing everything in the front bay and it will take some modifications to get it to fit just right. I will also be using 10/12mm EKWB PETG tubing.

Please stay tuned for weekly updates of the case mod/ build as it progresses. Thanks