- Joined

- Apr 3, 2015

- Location

- Planet Earth

Ok I got the algea or something!!!

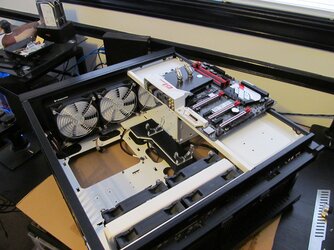

For my first multi-loop set-up I guess its bound to happen to most everyone??

BUT

for the first fill I used all the expensive Koolance stuff and was instructed NOT to add anything else.

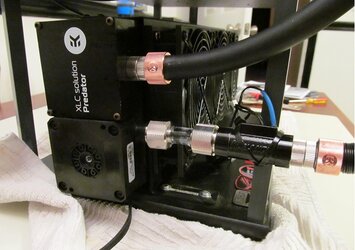

In fact the GPU loops are just about 100% Koolance hardware...

Anyway, going forward I am making my own "mix", but this really bothers me!!

Not a ton of run time(~25 hours ambient 20C) and some sitting around, but I always try to let it run a bit when not actively using.

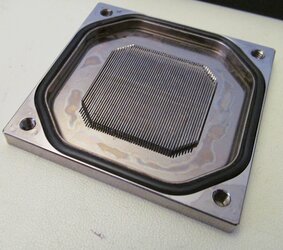

Started in the cpu loop and then a few days latter it was everywhere!

Any ideas as to why and if I have a beef with Koolance? (Nothing was damaged, so far that I know. I am servicing everything before re-rig.

See http://www.overclockers.com/forums/...dename-XmasList-project?p=7977536#post7977536

for more pics...

EDIT: Added pic per JB

Thanks for any feedback or stern lesson's learned advice

Salud

For my first multi-loop set-up I guess its bound to happen to most everyone??

BUT

for the first fill I used all the expensive Koolance stuff and was instructed NOT to add anything else.

In fact the GPU loops are just about 100% Koolance hardware...

Anyway, going forward I am making my own "mix", but this really bothers me!!

Not a ton of run time(~25 hours ambient 20C) and some sitting around, but I always try to let it run a bit when not actively using.

Started in the cpu loop and then a few days latter it was everywhere!

Any ideas as to why and if I have a beef with Koolance? (Nothing was damaged, so far that I know. I am servicing everything before re-rig.

See http://www.overclockers.com/forums/...dename-XmasList-project?p=7977536#post7977536

for more pics...

EDIT: Added pic per JB

Thanks for any feedback or stern lesson's learned advice

Salud

Last edited: