- Joined

- Sep 13, 2015

So I have begun to stockpile a large amount of different TIMS and figured I would try my hand at testing them against each other. Before I go wasting all of my TIM and time I figured I would get peoples input on testing procedures to keep the testing as informative as possible. I will lay out my proposed testing procedure below and I am hoping for some feedback on what is good and what is bad.

I realize that there will be a margin of error based off of my testing procedure and once I have a set procedure I can then determine what that margin of error is and take it into account in my testing.

So testing procedure,

Equipment used

Hardware-

I7-6700K @ 4.7ghz core and 4.4ghz cache running 1.35vcore

Asus MAximus VIII Gene

Corsair Dominator Platinums @ 3600 16-18-18-36 running 1.35v

Radeon X300SE passively cooled running in x4 slot provided by PCH

EVGA 750w G2

Cooling-

EK-Supremacy Evo CPU block with Koolance VL4N QDC

EK D5 pump with EK-XTOP

Swiftech Micro-res

Phobya Supernova 1260 radiator

The motherboard and Ram is cooled with one fan on the front and one fan on the back of the motherboard.

Testing Procedure

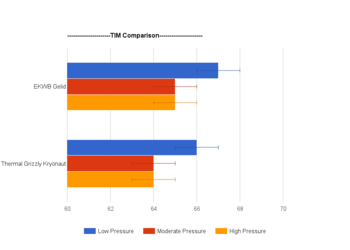

Each TIM will be tested under "Low", "Moderate", and "High" pressure. Each pressure will be tested with 3 separate mounts. After each mount the system will be run for 5 hours under the XTU stress test. Core temperatures and Water temperatures will be logged using HWInfo64 at a 1 second interval. Temperature reporting will be done based on the deltaT of the core temp and water temp. A full run graph will be generated using a 30 second running average of the deltaT. An average max temp will be generated from all 3 runs as well as a best max temp, these temperatures will be taken after the "Burn in" period has occurred and will also be based off of a 30 second rolling average. Max variation of core to core temp will also be reported for each run. In the case of an erroneous result(3% out of line with other 2 runs) the run will be dropped and a new mount will be performed.

Each mount will be performed with the TIM being applied in a single "Pea sized" blob placed in the center of the IHS, if time permits I may go back and test manufacturers recommended mounting procedures. Between each mount the IHS and CPU block will be cleaned with Arctic Clean Thermal Material Remover and then 91% Isopropyl alcohol.

That is about what I have for now let me know your thoughts. I would rather have you shoot holes in my testing or theory now then after I go through the time to test all of this material so please do not hold back on the criticism. I am not dead set on my testing procedures and am willing to modify them to best suiut the information the community will benefit from.

Thanks-Lochekey

I realize that there will be a margin of error based off of my testing procedure and once I have a set procedure I can then determine what that margin of error is and take it into account in my testing.

So testing procedure,

Equipment used

Hardware-

I7-6700K @ 4.7ghz core and 4.4ghz cache running 1.35vcore

Asus MAximus VIII Gene

Corsair Dominator Platinums @ 3600 16-18-18-36 running 1.35v

Radeon X300SE passively cooled running in x4 slot provided by PCH

EVGA 750w G2

Cooling-

EK-Supremacy Evo CPU block with Koolance VL4N QDC

EK D5 pump with EK-XTOP

Swiftech Micro-res

Phobya Supernova 1260 radiator

The motherboard and Ram is cooled with one fan on the front and one fan on the back of the motherboard.

Testing Procedure

Each TIM will be tested under "Low", "Moderate", and "High" pressure. Each pressure will be tested with 3 separate mounts. After each mount the system will be run for 5 hours under the XTU stress test. Core temperatures and Water temperatures will be logged using HWInfo64 at a 1 second interval. Temperature reporting will be done based on the deltaT of the core temp and water temp. A full run graph will be generated using a 30 second running average of the deltaT. An average max temp will be generated from all 3 runs as well as a best max temp, these temperatures will be taken after the "Burn in" period has occurred and will also be based off of a 30 second rolling average. Max variation of core to core temp will also be reported for each run. In the case of an erroneous result(3% out of line with other 2 runs) the run will be dropped and a new mount will be performed.

Each mount will be performed with the TIM being applied in a single "Pea sized" blob placed in the center of the IHS, if time permits I may go back and test manufacturers recommended mounting procedures. Between each mount the IHS and CPU block will be cleaned with Arctic Clean Thermal Material Remover and then 91% Isopropyl alcohol.

That is about what I have for now let me know your thoughts. I would rather have you shoot holes in my testing or theory now then after I go through the time to test all of this material so please do not hold back on the criticism. I am not dead set on my testing procedures and am willing to modify them to best suiut the information the community will benefit from.

Thanks-Lochekey