- Joined

- Sep 30, 2014

- Location

- Porto Alegre - RS - Brazil

Hello everyone!

I am not new to water cooling but I haven't really built anything in a while.

Last time I upgraded my system I turned back to air cooling because of some sh*t I found in the loop:

I believe it was result of the corrosion of aluminum parts inside the radiator.

Also, I was upgrading the GPU, so I had to turn down my awesome EK full coverage water blocks.

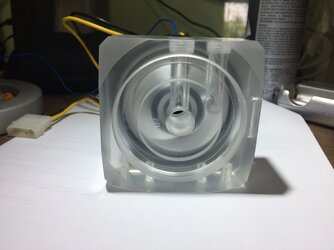

My reservoir was also showing some crackles.

So, with my reservoir looking bad, radiator gone, GPU water blocks gone and the money invested in new parts: MOBO, PSU, CPU and GPU, it just made sense to go air cooling and save some of the liquid fun for later.

That was good because I saw some rigid tubing loops and I fell in love with that looking and the idea of learning some new tricks.

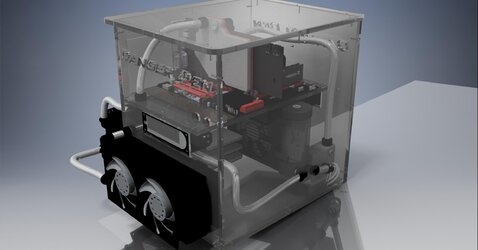

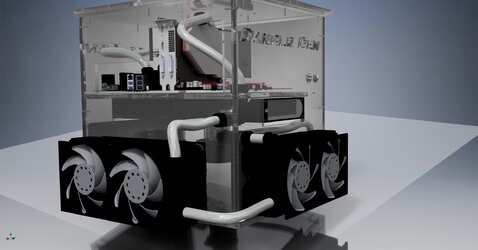

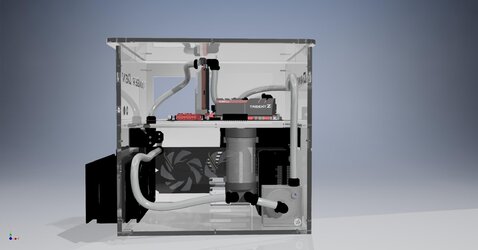

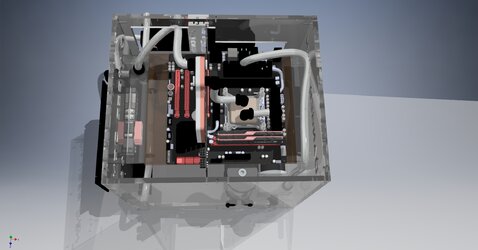

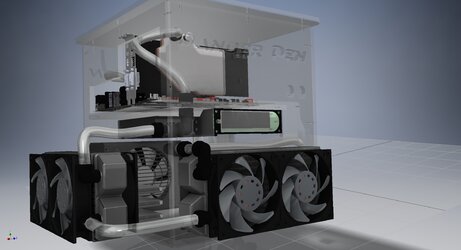

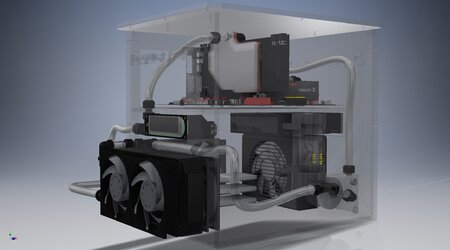

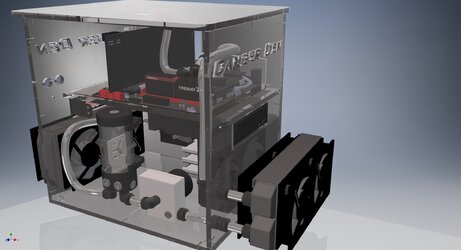

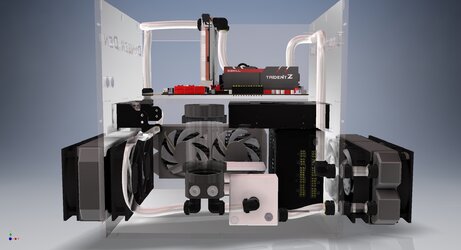

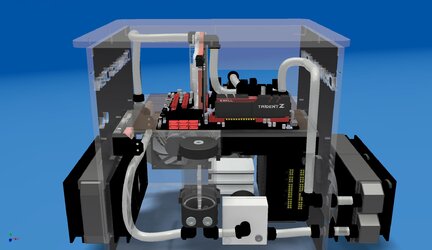

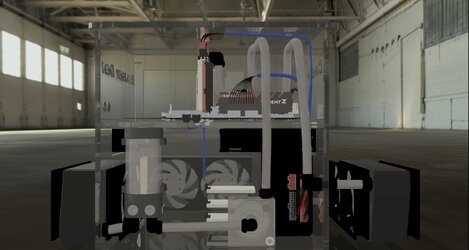

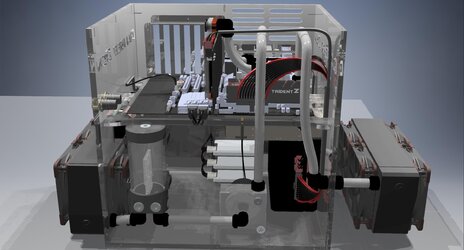

I have an old case though, a Danger Den Water Box Plus, which I plan to reuse for this build.

I know, it's acrylic, all transparent and old fashioned, but it still looks darn good and it seems easy enough to mod if necessary.

The case itself is amazing, but it leaves nothing to imagination, I have to improve my skills on cable management because I cannot hide it anywhere in this case - no pun intended.

So, here is what I have today:

Don't be scared by the looks, this is just a temporary arrengement for the system to work.

I feel like I have good components here and with your help I am going to sleeve these cables, put some lighting, watercool it and make it look awesome.

Even though I am not new to water cooling, my objectives in the past were always silence and performance, almost never aesthetics.

So, I expect this time to struggle a little with sleeving and cable management, as well as dealing with rigid tubing.

Here is the hardware I have today:

I know the GPU sucks, but I will upgrade it that later, I promise.

I use this rig for a little gaming and a lot of work, which includes Autocad, 3D rendering and some heavy ****.

In my next post I will go through what I am planning to do and gather some ideas.

I have some specific questions that I hope this forum can help.

Cheers!

Marcelo

I am not new to water cooling but I haven't really built anything in a while.

Last time I upgraded my system I turned back to air cooling because of some sh*t I found in the loop:

I believe it was result of the corrosion of aluminum parts inside the radiator.

Also, I was upgrading the GPU, so I had to turn down my awesome EK full coverage water blocks.

My reservoir was also showing some crackles.

So, with my reservoir looking bad, radiator gone, GPU water blocks gone and the money invested in new parts: MOBO, PSU, CPU and GPU, it just made sense to go air cooling and save some of the liquid fun for later.

That was good because I saw some rigid tubing loops and I fell in love with that looking and the idea of learning some new tricks.

I have an old case though, a Danger Den Water Box Plus, which I plan to reuse for this build.

I know, it's acrylic, all transparent and old fashioned, but it still looks darn good and it seems easy enough to mod if necessary.

The case itself is amazing, but it leaves nothing to imagination, I have to improve my skills on cable management because I cannot hide it anywhere in this case - no pun intended.

So, here is what I have today:

Don't be scared by the looks, this is just a temporary arrengement for the system to work.

I feel like I have good components here and with your help I am going to sleeve these cables, put some lighting, watercool it and make it look awesome.

Even though I am not new to water cooling, my objectives in the past were always silence and performance, almost never aesthetics.

So, I expect this time to struggle a little with sleeving and cable management, as well as dealing with rigid tubing.

Here is the hardware I have today:

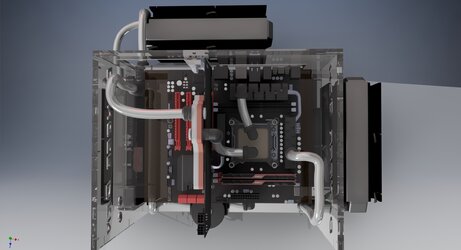

- MOBO Asus Maximus Vii Formula Intel Z97

- Processor Intel I7 4790k 4.0ghz 1175

- RAM Corsair Vengeance Pro 16gb (2 X 8 Gb) 2400mhz

- Blu-ray Lg Black Wh16ns40 Cache 4mb Sata

- NVidia GeForce GTX 760

- Thermaltake 850w modular PS-TPG-0850MPCGUS-1

- Ssd Samsung 840 Evo Mz-7te500bw 2.5 500gb Sata Iii

- HDD WD Black 1Tb

- HDD WD WD10JPLX-00MBPT0 500Gb

I know the GPU sucks, but I will upgrade it that later, I promise.

I use this rig for a little gaming and a lot of work, which includes Autocad, 3D rendering and some heavy ****.

In my next post I will go through what I am planning to do and gather some ideas.

I have some specific questions that I hope this forum can help.

Cheers!

Marcelo