- Joined

- May 8, 2011

- Location

- Darlington, South Carolina

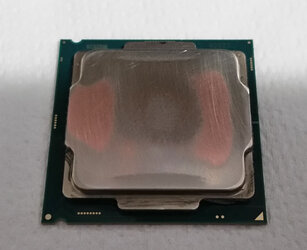

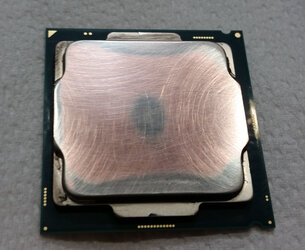

With my chilled water cooling setup I use regular CPU water blocks to actually cool the CPU itself I had an idea to experiment with modifying an already great performing water block to see if it's cooling could be improved and since it has turned out to be successful I am going to share it here with you all.

When I first got my EK Supremacy EVO water block it was to replace my XSPC Raystorm water block because reviews confirmed and reported the EVO was a better cooling performer which turned out to be true, with only swapping out the water block in my overclocked machine changing no settings, the EVO beat the Raystorm by 5c hottest core under Intel Burn Test load stress testing.

I basically shelved the Raystorm as a backup block for over a year then decided it was time to pull the EVO and clean it, but before I did that I opened the Raystorm up to make sure it was clean and ready to be mounted, when I did that and visually inspected the fin grid cut into the copper base plate I was not pleased with what I saw, the fin grids were flat on top and super tight together and 2 of the fin grids were actually touching each other.

So I broke out a razor blade to separate the grids touching each other and got them aligned, took a magnifying glass and after further inspection decided I had to do more than that, IMO, the cooling fins could possibly be improved to allow better coolant flow through them.

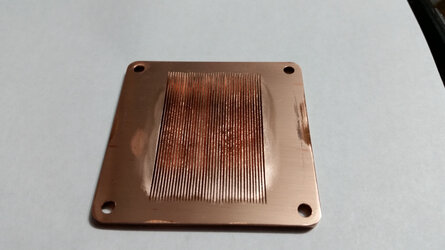

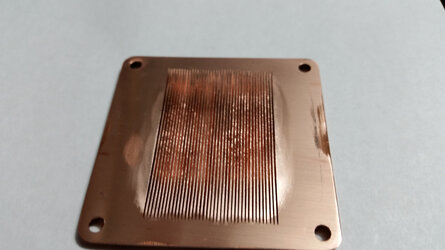

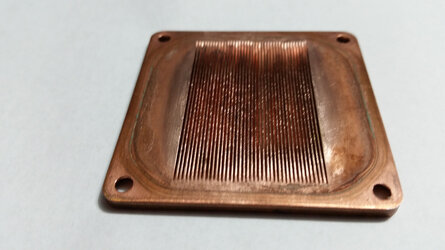

I broke out my Dremel tool and used a stainless steel rotary brush and very carefully, and painstakingly, spent close to an hour using it to widen the gaps of the fin grids, the stainless steel brush worked absolutely fantastic, it actually rounded the flat tops of the fins, widened the channels, and cut the copper slots a little deeper.

The stainless steel is much harder than the copper and it will cut the copper so you have to be careful and stay away from the flat copper edge where the rubber gasket runs, don't get scratches over there or the block will leak when reassembled.

Which I learned the hard way!, and ended up using a very thin layer of marine grade silicon to seal the water block, but if you don't scratch the gasket seal area you won't have a problem with any leaks.

Once the modified water block was confirmed as being leak free I swapped it out with the EK EVO and instantly under the exact same testing even with a fresh application of Artic Silver 5, (which we all know AS5 requires cure in time), the Raystorm actually beat the EVOs cooling performance by 2c.

So the fin grid modifications in the copper base plate have actually improved the Raystorms thermal cooling performance enough to surpass the EVOs cooling performance.

I truly wish I had taken before and after pictures but I did not even know this was going to work at all, my thoughts were simply if I mess it up well I am not using it right now anyway, I do however have a picture of the copper base plate after the modification was completed, and the stainless steel brush I used in the Dremel tool.

![ATTACH]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![ATTACH]](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

After seeing the picture the cell phone took which is pretty amazing for a cell phone I will probably take it back apart and further modify the fins as they still look rough in the picture that's why I wish I had taken a before picture as they were almost closed up they were so tight.

Anyway FYI, the Raystorms cooling performance did improve from the modification to the fin grids.

Ryan

When I first got my EK Supremacy EVO water block it was to replace my XSPC Raystorm water block because reviews confirmed and reported the EVO was a better cooling performer which turned out to be true, with only swapping out the water block in my overclocked machine changing no settings, the EVO beat the Raystorm by 5c hottest core under Intel Burn Test load stress testing.

I basically shelved the Raystorm as a backup block for over a year then decided it was time to pull the EVO and clean it, but before I did that I opened the Raystorm up to make sure it was clean and ready to be mounted, when I did that and visually inspected the fin grid cut into the copper base plate I was not pleased with what I saw, the fin grids were flat on top and super tight together and 2 of the fin grids were actually touching each other.

So I broke out a razor blade to separate the grids touching each other and got them aligned, took a magnifying glass and after further inspection decided I had to do more than that, IMO, the cooling fins could possibly be improved to allow better coolant flow through them.

I broke out my Dremel tool and used a stainless steel rotary brush and very carefully, and painstakingly, spent close to an hour using it to widen the gaps of the fin grids, the stainless steel brush worked absolutely fantastic, it actually rounded the flat tops of the fins, widened the channels, and cut the copper slots a little deeper.

The stainless steel is much harder than the copper and it will cut the copper so you have to be careful and stay away from the flat copper edge where the rubber gasket runs, don't get scratches over there or the block will leak when reassembled.

Which I learned the hard way!, and ended up using a very thin layer of marine grade silicon to seal the water block, but if you don't scratch the gasket seal area you won't have a problem with any leaks.

Once the modified water block was confirmed as being leak free I swapped it out with the EK EVO and instantly under the exact same testing even with a fresh application of Artic Silver 5, (which we all know AS5 requires cure in time), the Raystorm actually beat the EVOs cooling performance by 2c.

So the fin grid modifications in the copper base plate have actually improved the Raystorms thermal cooling performance enough to surpass the EVOs cooling performance.

I truly wish I had taken before and after pictures but I did not even know this was going to work at all, my thoughts were simply if I mess it up well I am not using it right now anyway, I do however have a picture of the copper base plate after the modification was completed, and the stainless steel brush I used in the Dremel tool.

After seeing the picture the cell phone took which is pretty amazing for a cell phone I will probably take it back apart and further modify the fins as they still look rough in the picture that's why I wish I had taken a before picture as they were almost closed up they were so tight.

Anyway FYI, the Raystorms cooling performance did improve from the modification to the fin grids.

Ryan

so I had to break out the brush and fine tune it further.

so I had to break out the brush and fine tune it further.