- Joined

- Sep 7, 2013

Hope you get better Bob!

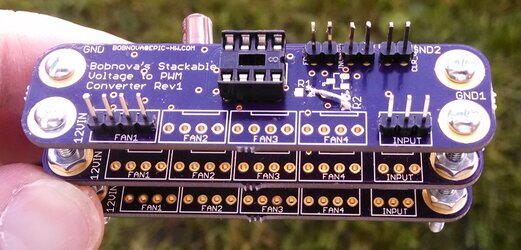

Looks good to me.

I love PCB's and dabbling with circuits and stuff, but I won't lie. I have no idea where to begin even building a circuit like that.

So hat's off to you

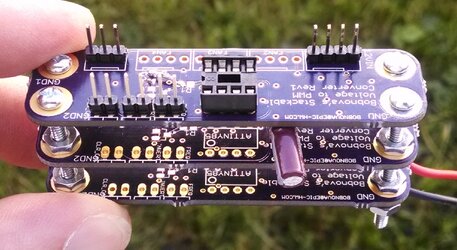

Looks good to me.

I love PCB's and dabbling with circuits and stuff, but I won't lie. I have no idea where to begin even building a circuit like that.

So hat's off to you