- Joined

- Mar 7, 2011

- Location

- Bay Area

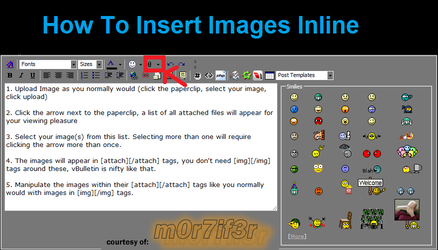

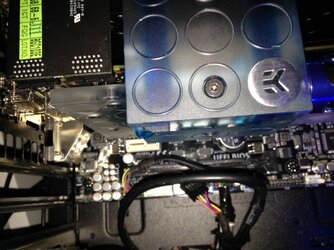

Hey Group. I just got my 3 way sli up and running. the bridge is an EK FC Bridge Triple Parallel CSQ, attached to a EK GeForce 680 GTX+ VGA Liquid Cooling Block. These are the blocks that fit the GTX 670 FTW. Anyhow the connection on the bottom card has a slow drip. I have changed the seal three times, and attempted to remove all debris around the connection, but to no avail, it still drips. Luckily this last cleaning slowed the drip way down. Do I need new parts? Seals? Prime 95 to melt it in there? Is the weight of three cards an issue? Any help is appreciated.

Thanks!

Thanks!