Tubing project as promised to some.

Old Tubing were Primochill, installed just 3 weeks ago.

they went CLOUDED in 1 week.. and I was worried.

I added silver coil and CuS04 in the old loop.. after 3 weeks, the pH is at 5.9.. I call that not ideal at all.

So my stuff ordered from performance-pcs came.. and work begun:

first look at the old system

pretty much.. white tubes...

I took apart. and lets look at the tubing.. you can see area without water contact is still clear.. so that rounds it down to the liquid's contact causing this..

another look here, you can see the film is actually getting thick.. I think I made the right call taking the whole thing apart..

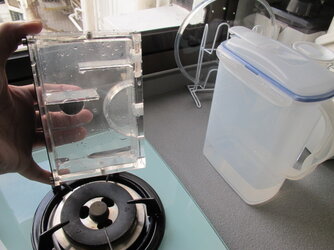

Always wash before work. You will see my rads here. 2 are from swiftech, and one is a BlackIceStealth. Can you tell which is which? haha. So you know, the tank of water there.. is deionized water.

Here's the res.. looks ok.. I thought there was a white film too, turns out to be fog only.

taking EVERYTHING apart..

Here's the koolance cpu 37 after lapping. mirrorly and 'slightly' concave, perfect.

this time, I use Artic Silver5 as TIM, was using MX-4, so just going up the ladder. AS5 is not bad.. spreads easy, right viscosity for good use. Expensive though.. the instruction says this is the kind of TIM that takes 2 days to set in... and can experience a full 1'C difference.. we will see.

this is a picture of my placing down the block, removing it to check for contacts. (I always always do that.)

New VRM and SouthBridge waterblock now installed. Kinda an overkill... but hey, if koolance made a R4E specific waterblock.. I want it. I also self made a PSU partial cover with a piece of metal painted black. Now I can put my pump on it !

worked from 4pm - 4am.. no kidding...

completed. Let me introduce my components.

Top Fans are SLIPSTREAM 1900 rpm, they are awesome, works fine, lowered temps than GT-AP15s, they are in a PUSH/PULL set up.

back fan is a Enermax Duo 1700 rpm arg 85CFM, also push/pull, but the pulling partner is another SS1900. I just have the Enermax here for the good looks.

Bottom rad, I have 2 SS1900 as push, not push/pull there.. running out of room on my box.. TUBES, are now Masterkleer 1/2 ID. they do something special.

that is this:

Tube are UV reactive. I think it looks nice.

another closer look.

Now lets hope this time. With JUST silver coil and distill, it won't cloud anytime soon. A serious pain in the butt to redo it.

Thanks.

Old Tubing were Primochill, installed just 3 weeks ago.

they went CLOUDED in 1 week.. and I was worried.

I added silver coil and CuS04 in the old loop.. after 3 weeks, the pH is at 5.9.. I call that not ideal at all.

So my stuff ordered from performance-pcs came.. and work begun:

first look at the old system

pretty much.. white tubes...

I took apart. and lets look at the tubing.. you can see area without water contact is still clear.. so that rounds it down to the liquid's contact causing this..

another look here, you can see the film is actually getting thick.. I think I made the right call taking the whole thing apart..

Always wash before work. You will see my rads here. 2 are from swiftech, and one is a BlackIceStealth. Can you tell which is which? haha. So you know, the tank of water there.. is deionized water.

Here's the res.. looks ok.. I thought there was a white film too, turns out to be fog only.

taking EVERYTHING apart..

Here's the koolance cpu 37 after lapping. mirrorly and 'slightly' concave, perfect.

this time, I use Artic Silver5 as TIM, was using MX-4, so just going up the ladder. AS5 is not bad.. spreads easy, right viscosity for good use. Expensive though.. the instruction says this is the kind of TIM that takes 2 days to set in... and can experience a full 1'C difference.. we will see.

this is a picture of my placing down the block, removing it to check for contacts. (I always always do that.)

New VRM and SouthBridge waterblock now installed. Kinda an overkill... but hey, if koolance made a R4E specific waterblock.. I want it. I also self made a PSU partial cover with a piece of metal painted black. Now I can put my pump on it !

worked from 4pm - 4am.. no kidding...

completed. Let me introduce my components.

Top Fans are SLIPSTREAM 1900 rpm, they are awesome, works fine, lowered temps than GT-AP15s, they are in a PUSH/PULL set up.

back fan is a Enermax Duo 1700 rpm arg 85CFM, also push/pull, but the pulling partner is another SS1900. I just have the Enermax here for the good looks.

Bottom rad, I have 2 SS1900 as push, not push/pull there.. running out of room on my box.. TUBES, are now Masterkleer 1/2 ID. they do something special.

that is this:

Tube are UV reactive. I think it looks nice.

another closer look.

Now lets hope this time. With JUST silver coil and distill, it won't cloud anytime soon. A serious pain in the butt to redo it.

Thanks.

So you think dual 4" is plenty of light? I am just doing a CPU block.

So you think dual 4" is plenty of light? I am just doing a CPU block.