- Joined

- Sep 10, 2013

Hi everyone - I was ask if I would post this work log On Overclockers by GTXJackBauer.

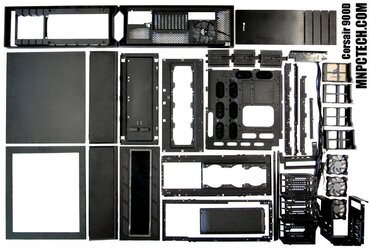

This is an ongoing build that started about two months before the Corsair 900D was available.

This is a tribute build to the band Metallica. I have come to find that they are a lightning rod. You either love them or hate them,

but above all this is a computer build and I hope you will let my work show my passion for our hobby.

This Is corporative build. My name is Mike ( onevoicewild ) I am Building a Corsair 900D Case Mod, I live in the USA.

My Good friend Sam ( Do Until Loopy ) lives in London UK and he is doing all the renderings and developed the design based on my original Ideas.

Proudly Sponsored By :

This was my Original Inspiration for the theme, I like the way it looks and a lot of people

are doing game themes so I wanted to try something a little different.

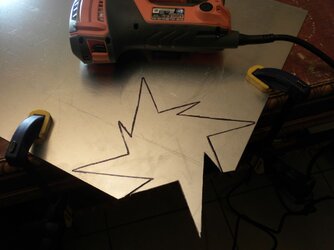

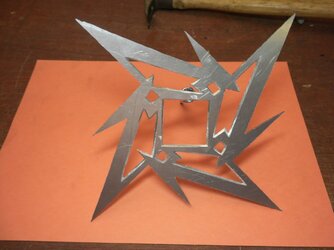

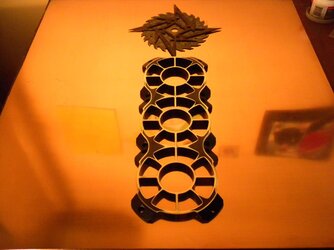

I started working on the front emblem for the case. This came to be known as the spiky thing.

I think it drew enough blood from me to earn it's name. I have Made most of the pieces by hand,

out of necessity to keep costs down.

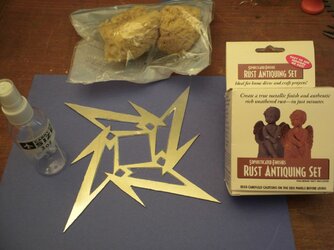

I used rusting techniques and paint splotching to get the colors I was looking for.

I was very happy with the way It came out. I went through several saw blades trying to find one that was acceptable,

Most blades these days look like something out of alien and not the traditional look I needed.

We have multiple versions of the case that we were considering for the final finish.

The standard version.

This is the Heavy Metal version, which seems to be the favored look.

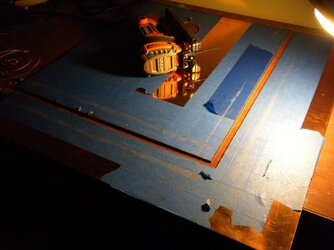

I was fortunate to have a heavy sheet of Copper about 26" x 27" 3mm thick and about 27 pounds.

The current cost of a sheet like this would be $$$$ It had an acid etching on the other side

but I decided it had to be sacrificed to the Modding gods. The down side is that I'm using the back side that had

a lot of deep scratches that continue to plague me continually. Lets just say my upper body strength is increasing daily.

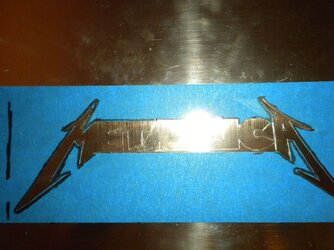

Next on the agenda it to craft the Metallica emblem.

Well every thing has to start somewhere. Ruff, Ruff my kingdom for a CNC machine. ha ha

Fortunately one of my personal traits is extreme stubbornness ! This took a full week of 2 to 3 hours a night cutting,

filing and polishing. Big Pain, but there is truly a great satisfaction in being able to craft something with basic tools.

When your modding a case that isn't available you tend to have a little time on your hands. Oh my hands !

I'm good with that ! It came out better than I hoped for. I have to say that Sam's whole world is exact precision

and having him looking over my shoulder has helped me bring up my game to a higher level. I had to Laugh,

after it was done he liked it but had to point out that the edge bevels were done at 45 degree angles and not the prescribed

30 degree angle. Ha Ha there are just some places you can't get needle files into, no matter how small they are !

But that kind of attitude pushes me to do a better job than I might without Sam pushing me for perfection.

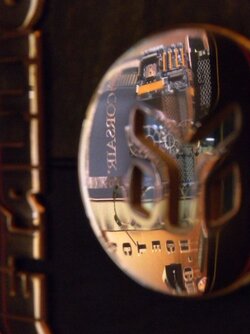

I love how moody this polished Copper is, depending on how the light hits it.

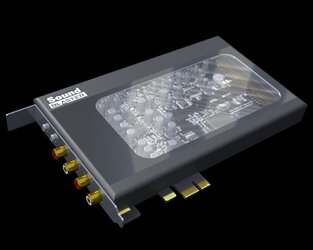

One of the programs Sam uses for his renderings Is solidworks.

One cool thing about it is you build components separately and

then you can plug them into anything.

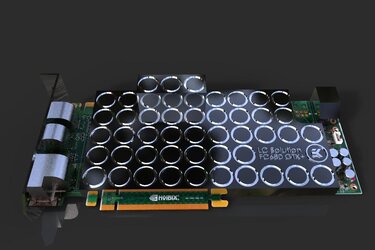

Here is his render of my sound card.

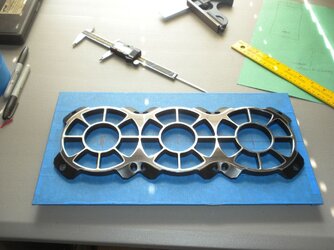

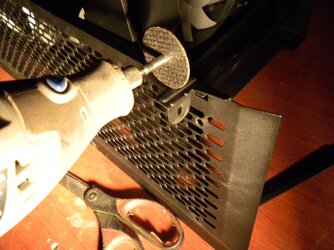

Bill Owen at MNPCTECH made me some very special grills for The Metallica Build.

He made two 200mm Nautilus grills and a quad ring OverKill grill. These beautiful grills

are key to the overall look of the case.

Just to give you an Idea of how large these grills are, that is an 140mm fan behind it.

I hate people getting finger prints on my fan blades so I wanted to add some deterrents to go along with the theme.

The crazy thing is that I may not even be using these 200mm fans on this build.

People had been pushing me to use a 360 Nautilus grill on the front instead of the two 200mm.

I had that grill on my 800D so I temporarily robbed it to see what kind of a finish I could get on it.

Once I was done I swung over to the 360 camp.

The red headed step child. My 800D

Bill Owen had ask me if I needed another 360 grill to replace the one I was robbing of the 800D. I told him oh no I won't need one.

My 800D said WHAT? Parts cost $ 0 Dollars Shipping cost $ 0 Dollars

Stealing parts from the rig your currently using - Priceless !

This is one of my prize toy's, when I first saw one of these I knew I had to have one!

So I have to ask myself the question ? why do I have a sanding block in my hand ?

As modders we want to make something unique. Manufactures can only stock the stuff that sells,

It's up to us to take it from there.

There is a reason that people Anodize things. It's very durable and in this case, very hard to sand off.

This actually turned out to be my saving grace. All I had was fairly fine sand cloth so it was going slowly.

The plan was to flat sand and polish the top like I did on the 200mm grills. I almost wish I had stopped

where I was at the picture below, but that wasn't the plan and I hadn't yet realized how interesting

the developing pattern was becoming.

Once I pushed on I started to realize just how good it was looking so

I decided to see what I could do with it. I was very happy with the

outcome and that's why I decided to go with the 360 Grill on the front Bezel.

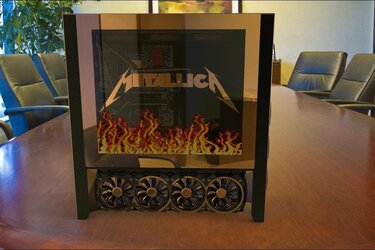

Sam wanted to do some renders in an office setting. Metallica has to have an office somewhere?

I don't imagine it being this clean, but hey maybe the groupies needed something to do between shows?

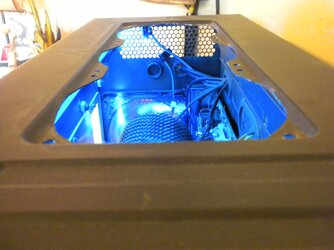

Here Is a night shot to test the lighting. Solidworks is amazing, look at the shadows above the case,

it actually casts light the way it would be if the lights were in place.

Here Is an early Rad that was rendered, but once we got better products from EK

we will not be using it ! but I owe it to Sam for taking the time to do it.

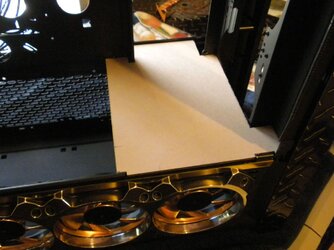

I promise there is an actual case mod in this log, but up to this point no 900D's

were available so we were keeping busy. this turns out in our favor as I will show you.

This is an ongoing build that started about two months before the Corsair 900D was available.

This is a tribute build to the band Metallica. I have come to find that they are a lightning rod. You either love them or hate them,

but above all this is a computer build and I hope you will let my work show my passion for our hobby.

This Is corporative build. My name is Mike ( onevoicewild ) I am Building a Corsair 900D Case Mod, I live in the USA.

My Good friend Sam ( Do Until Loopy ) lives in London UK and he is doing all the renderings and developed the design based on my original Ideas.

Proudly Sponsored By :

This was my Original Inspiration for the theme, I like the way it looks and a lot of people

are doing game themes so I wanted to try something a little different.

I started working on the front emblem for the case. This came to be known as the spiky thing.

I think it drew enough blood from me to earn it's name. I have Made most of the pieces by hand,

out of necessity to keep costs down.

I used rusting techniques and paint splotching to get the colors I was looking for.

I was very happy with the way It came out. I went through several saw blades trying to find one that was acceptable,

Most blades these days look like something out of alien and not the traditional look I needed.

We have multiple versions of the case that we were considering for the final finish.

The standard version.

This is the Heavy Metal version, which seems to be the favored look.

I was fortunate to have a heavy sheet of Copper about 26" x 27" 3mm thick and about 27 pounds.

The current cost of a sheet like this would be $$$$ It had an acid etching on the other side

but I decided it had to be sacrificed to the Modding gods. The down side is that I'm using the back side that had

a lot of deep scratches that continue to plague me continually. Lets just say my upper body strength is increasing daily.

Next on the agenda it to craft the Metallica emblem.

Well every thing has to start somewhere. Ruff, Ruff my kingdom for a CNC machine. ha ha

Fortunately one of my personal traits is extreme stubbornness ! This took a full week of 2 to 3 hours a night cutting,

filing and polishing. Big Pain, but there is truly a great satisfaction in being able to craft something with basic tools.

When your modding a case that isn't available you tend to have a little time on your hands. Oh my hands !

I'm good with that ! It came out better than I hoped for. I have to say that Sam's whole world is exact precision

and having him looking over my shoulder has helped me bring up my game to a higher level. I had to Laugh,

after it was done he liked it but had to point out that the edge bevels were done at 45 degree angles and not the prescribed

30 degree angle. Ha Ha there are just some places you can't get needle files into, no matter how small they are !

But that kind of attitude pushes me to do a better job than I might without Sam pushing me for perfection.

I love how moody this polished Copper is, depending on how the light hits it.

One of the programs Sam uses for his renderings Is solidworks.

One cool thing about it is you build components separately and

then you can plug them into anything.

Here is his render of my sound card.

Bill Owen at MNPCTECH made me some very special grills for The Metallica Build.

He made two 200mm Nautilus grills and a quad ring OverKill grill. These beautiful grills

are key to the overall look of the case.

Just to give you an Idea of how large these grills are, that is an 140mm fan behind it.

I hate people getting finger prints on my fan blades so I wanted to add some deterrents to go along with the theme.

The crazy thing is that I may not even be using these 200mm fans on this build.

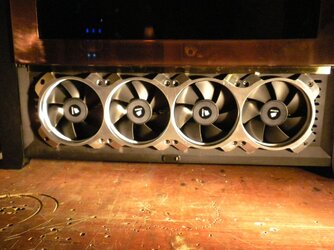

People had been pushing me to use a 360 Nautilus grill on the front instead of the two 200mm.

I had that grill on my 800D so I temporarily robbed it to see what kind of a finish I could get on it.

Once I was done I swung over to the 360 camp.

The red headed step child. My 800D

Bill Owen had ask me if I needed another 360 grill to replace the one I was robbing of the 800D. I told him oh no I won't need one.

My 800D said WHAT? Parts cost $ 0 Dollars Shipping cost $ 0 Dollars

Stealing parts from the rig your currently using - Priceless !

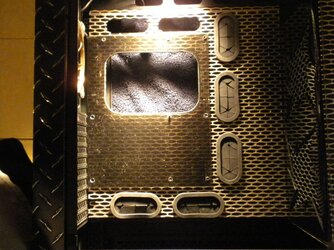

This is one of my prize toy's, when I first saw one of these I knew I had to have one!

So I have to ask myself the question ? why do I have a sanding block in my hand ?

As modders we want to make something unique. Manufactures can only stock the stuff that sells,

It's up to us to take it from there.

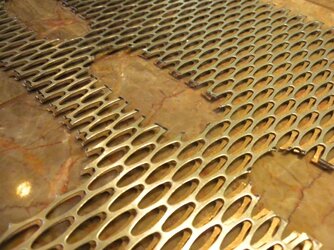

There is a reason that people Anodize things. It's very durable and in this case, very hard to sand off.

This actually turned out to be my saving grace. All I had was fairly fine sand cloth so it was going slowly.

The plan was to flat sand and polish the top like I did on the 200mm grills. I almost wish I had stopped

where I was at the picture below, but that wasn't the plan and I hadn't yet realized how interesting

the developing pattern was becoming.

Once I pushed on I started to realize just how good it was looking so

I decided to see what I could do with it. I was very happy with the

outcome and that's why I decided to go with the 360 Grill on the front Bezel.

Sam wanted to do some renders in an office setting. Metallica has to have an office somewhere?

I don't imagine it being this clean, but hey maybe the groupies needed something to do between shows?

Here Is a night shot to test the lighting. Solidworks is amazing, look at the shadows above the case,

it actually casts light the way it would be if the lights were in place.

Here Is an early Rad that was rendered, but once we got better products from EK

we will not be using it ! but I owe it to Sam for taking the time to do it.

I promise there is an actual case mod in this log, but up to this point no 900D's

were available so we were keeping busy. this turns out in our favor as I will show you.

Last edited: