I've been looking to get into water cooling again, as I need something to help with the temps. My old XP90-C just can't handle anything. When idle my E6300 is at ~60C. I was looking more stuff up today about the latest and greatest when the bong thread was bumped. So I started researching that. I can across Bing's friend's design.

The easy stuff:

I already have a Via Aqua 2300, it does 600 GPH and a 7' head. I think that should be good enough. Piping I'll get locally and tubing I'll get from mc-mastercarr. Back in the day I used masterkleer 7/16" . Is that still the preferred tubing?

For a water block I'm looking for something that is 775, 1155,AM3 compatible. Or only 775 if the price is right. I've seen that the EK-Supreme HF is suppose to be the best CPU block but it's $70-80 depending on the exact model. Is there any better options? There is a Danger Den block for $20 in the classifieds. There is also a Dtek Fusion V2 for $45. Any opinions on those?

Now on to the fun stuff:

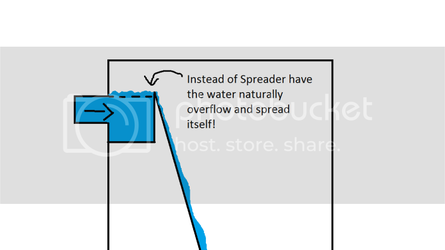

Lets start with the design itself.

View attachment 59948

I think I am going to put this into a 18 gallon storage bin. I can get them for $5 a piece. The dimension of 16.58"x16.20"x24.22" are right in line with what I was thinking. Now it's perfectly rectangular but works pretty well. I originally was going to use another pc case, as I have about 5 generic ones. However they are all very very holely.

I'm not sure what I am going to do about the fans yet. I know the design calls for squirrel cage fans but we'll see what solution is settle on. For the hot air exhaust I am going to make a change, and output the hot air to a p-trap. This should help collect and last condensation that is caught exiting and also help to keep the hot exhaust from blowing any of the condensation from the "roof" from being blown out. I'll put a drain at the bottom of the p-trap and feed it back to a reservoir. This will also help a small amount on the water loss.

I'm going to have misters at the top where the hot water is coming in, and I plan to use a metal plates, possibly copper from mcmastercarr for the tunnel.

For the misters I have orbit 90 degree shrub sprinklers. They are $0.77 at lowes. I combined that with $0.44 nipples, $0.56 threaded t, and a 10 foot piece of pvc for $1.55. I bought 5 sets of the mister setups. That should fit across the 16" pretty well. It's all 1/2". My pump is 3/4" barbs. We'll see what my water block is barbed at and that changes if I'll go 3/4" tubing or the 1/2" tubing through everything. If it's 3/4" I'll just use a reducer/brushing to go to 3/4 -> 1/2" for the misters.

The easy stuff:

I already have a Via Aqua 2300, it does 600 GPH and a 7' head. I think that should be good enough. Piping I'll get locally and tubing I'll get from mc-mastercarr. Back in the day I used masterkleer 7/16" . Is that still the preferred tubing?

For a water block I'm looking for something that is 775, 1155,AM3 compatible. Or only 775 if the price is right. I've seen that the EK-Supreme HF is suppose to be the best CPU block but it's $70-80 depending on the exact model. Is there any better options? There is a Danger Den block for $20 in the classifieds. There is also a Dtek Fusion V2 for $45. Any opinions on those?

Now on to the fun stuff:

Lets start with the design itself.

View attachment 59948

I think I am going to put this into a 18 gallon storage bin. I can get them for $5 a piece. The dimension of 16.58"x16.20"x24.22" are right in line with what I was thinking. Now it's perfectly rectangular but works pretty well. I originally was going to use another pc case, as I have about 5 generic ones. However they are all very very holely.

I'm not sure what I am going to do about the fans yet. I know the design calls for squirrel cage fans but we'll see what solution is settle on. For the hot air exhaust I am going to make a change, and output the hot air to a p-trap. This should help collect and last condensation that is caught exiting and also help to keep the hot exhaust from blowing any of the condensation from the "roof" from being blown out. I'll put a drain at the bottom of the p-trap and feed it back to a reservoir. This will also help a small amount on the water loss.

I'm going to have misters at the top where the hot water is coming in, and I plan to use a metal plates, possibly copper from mcmastercarr for the tunnel.

For the misters I have orbit 90 degree shrub sprinklers. They are $0.77 at lowes. I combined that with $0.44 nipples, $0.56 threaded t, and a 10 foot piece of pvc for $1.55. I bought 5 sets of the mister setups. That should fit across the 16" pretty well. It's all 1/2". My pump is 3/4" barbs. We'll see what my water block is barbed at and that changes if I'll go 3/4" tubing or the 1/2" tubing through everything. If it's 3/4" I'll just use a reducer/brushing to go to 3/4 -> 1/2" for the misters.

Last edited: