Hi Folks

Applied a few coats of conformal to my rive and mve but before proceeding, have a couple questions.

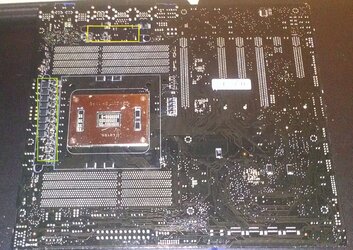

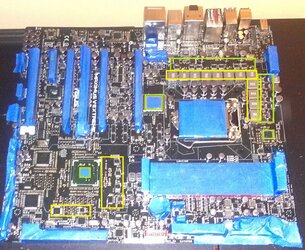

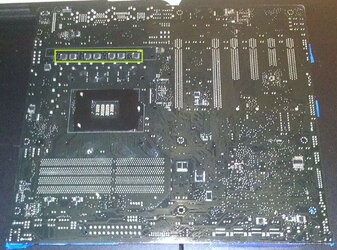

Below are pics of the front/back of each motherboard. Everything inside the green rectangles need to have their tops scraped of conformal. Am not sure about the stuff inside the yellow boxes, though as none of those parts is touching a heatsink. Am also not sure if there are any other parts that should be scraped on the top or bottom of either mobo. Thoughts? Just scrape the green? Scrape the yellow, too? Anything else that should be scraped?

Next question....any one know the thickness(es) of the thermal pads on the boards? They're in fine condition but prefer to replace them with nicer. Anyone know or will I just have to eyeball the thicknesses?

tia as always!

Applied a few coats of conformal to my rive and mve but before proceeding, have a couple questions.

Below are pics of the front/back of each motherboard. Everything inside the green rectangles need to have their tops scraped of conformal. Am not sure about the stuff inside the yellow boxes, though as none of those parts is touching a heatsink. Am also not sure if there are any other parts that should be scraped on the top or bottom of either mobo. Thoughts? Just scrape the green? Scrape the yellow, too? Anything else that should be scraped?

Next question....any one know the thickness(es) of the thermal pads on the boards? They're in fine condition but prefer to replace them with nicer. Anyone know or will I just have to eyeball the thicknesses?

tia as always!