eXCeSS said:

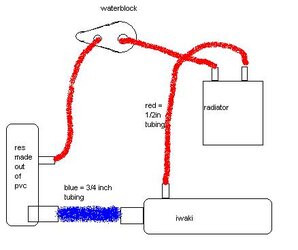

You could make a res out of 1" pvc with 2 caps 1 glued on one removable for filling. Drill 2 holes, epoxy in a 1/2in barb and a 3/4 inch barb, and have a 3/4 inch barb on the pump and run the big tubing from the res to the inlet of the pump..

eXCeSS,

Nice idea but I do believe that the design you are describing does not really benefit the inlet of the pump. I am saying this because pHaestus is saying that he used the same kind of design in his rig initially but that didn't provide any benefits for the pump.

What we need here is to be able to "submerge" the inlet of the pump in a reservoir so that the reservoir itself is like one huge barb fitting. Otherwise, if we just use 3/4" fittings to connect the pump to the reservoir, then we are restricting the flow with the 3/4" barb and it doesn't matter where the reservoir is placed in the system.

Think about it: Tube connects to the reservoir, reservoir connects to a fitting (1/2" or 3/4" or some other size) and the fitting connects to the pump. For the water to go from the reservoir to the pump, the barb you attached to the reservoir (connected to the pump) has to be used. As a result, the choke point is the barb and the reservoir is only providing a point in the system for filling/bleeding. Imagine just using 3/4" tubing for the pump and not using any barbs at all. This also accomplishes the same exact thing. You could add a reservoir to this kind of system somewhere between the pump and the tubing but it isn't going to make a difference where you put the reservoir because this time the 3/4" tubing that connects to the pump will become the choke point.

In short, unless you can attach the reservoir directly to the inlet of the pump, the reservoir is not going to provide any advantages for the pump. My problem here is figuring out how to build and securely attach a reservoir to the pump inlet without using any barbs like in pHaestus' setup. Will drilling a big hole in a PVC pipe and using goop do the trick?

Or is there a more elegant solution like using just acrylic?

If I wanted to build a cylinder out of acyrclic, what kind of tools do I need and how would I be able to do this? Also, is acryrlic easy to get a hold of? Can I just buy some from Home Depot for instance?