- Joined

- Dec 5, 2001

- Location

- Random Dumpster/Alley

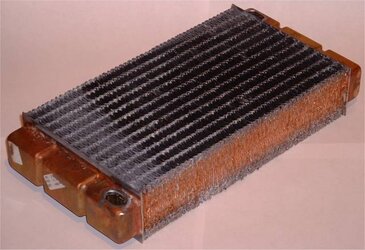

I was wondering about the side fins of the Fedco 2-342, the single-pass heater core for a Suburban. Looking at the attached picture, can side fins be cut off a bit as shown via Photoshopping it? I'm assuming the tubes are only between rows of fins (green lines) and not on the sides, equaling 13 total?

The reason why I ask is because I'm now considering changing my idea to put the radiator in the bottom of the case laying down. I want to use a single pass core, and had my mind set on a Bonneville core (and modding it to single-pass) since it's *just* within my max width dimention of 5.625". The problem with it is that its too long compaired to the Fedco 2-342 core, but the Fedco 2-342 core's prob is that its 6.125" wide. Each fin section seems to be ~.4" wide, so I'm guessing I could get just enough clearance if I shave those fins off both sides.

Can this be done?

ps: I already know a chevette core & expensive aftermarket rads would fit, but I don't want to use them.

The reason why I ask is because I'm now considering changing my idea to put the radiator in the bottom of the case laying down. I want to use a single pass core, and had my mind set on a Bonneville core (and modding it to single-pass) since it's *just* within my max width dimention of 5.625". The problem with it is that its too long compaired to the Fedco 2-342 core, but the Fedco 2-342 core's prob is that its 6.125" wide. Each fin section seems to be ~.4" wide, so I'm guessing I could get just enough clearance if I shave those fins off both sides.

Can this be done?

ps: I already know a chevette core & expensive aftermarket rads would fit, but I don't want to use them.