- Joined

- Mar 1, 2003

- Location

- Mechanicsburg, PA

This is a basic tutorial on subwoofer design using a free program called winISD. You will need to download and install winISD http://www.linearteam.dk/default.aspx?download=winisd .

Ok lets start off by explaining some of the basics. The audible frequencies range for humans is 20 to 20,000Hz. A subwoofer is a special speaker that handles all of the low bass frequencies in a sound system. They usually handle the frequencies from as high as 150 Hz and lower. This is a great page for seeing what instruments cover what frequency ranges http://www.psbspeakers.com/FrequenciesOfMusic.html.

A standard powered subwoofer is comprised of a few different parts. The main parts are the actually subwoofer driver, an enclosure for the driver, and amplifier, and a crossover.

I'll start with the driver first. The subwoofer driver is what reproduces the bass. Most subwoofers will use 10" or larger drivers to hit the lower bass notes. I will be using a Dayton DVC 12" subwoofer driver for the tutorial.

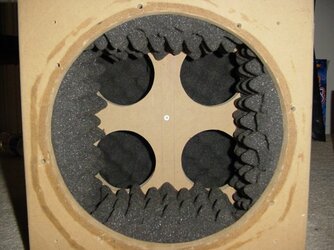

Now onto the enclosure. The enclosures purpose is to isolate the back wave of the subwoofer driver. There are several different ways to go about building an enclosure such as using sono tube (large diameter cardboard tube's) or the more traditional wood enclosure. There are also quite a few configurations ranging from sealed to passive radiator to ported etc. We will concentrate on only sealed and ported.

Now lets talk about amplifiers. There are largely two ways to go about powering your subwoofer. One way is to buy a plate amplifier designed for a subwoofer. The other is using a normal pro audio amplifier (you can use old stereo receivers etc but those are really not ideal solutions). The most convenient in my opinion is the plate amplifier option since it usually includes the crossover and mounts right in the speaker enclosure. It is most cost effective and should provide plenty of power for most subwoofers.

Then there is the crossover. The crossover separates the the frequencies so that the subwoofer doesn't receive any of the high frequency material. You can buy external crossovers or if you buy a plate amplifier it will usually have a crossover built in. Most subwoofers are crossed over at 100 hz or lower. Your actual crossover point you would use depends on your main speakers and the room the sound system is in.

Now that we have covered some of the basics lets start by setting a budget for the project. Most good subwoofers will cost around $200~300 minimum but it can be done for cheaper. once you have a budget set you can start seeing whats available around that price point. I would recommend looking at Parts Express, or madisound (I like their Dayton Audio DVC and Titanic series, as well as Tang band products but there are TONS of great options out there). As mentioned earlier I will be using a Dayton DVC 12" subwoofer for the tutorial.

They are a very good value for performance and can work well in larger or smaller enclosures. Once you have a driver selected you will need to get the T/S parameters do design the enclosure with winISD. This is a great page for learning about subwoofer design and they have a good explanation of T/S parameters etc. http://www.diysubwoofers.org/define.htm . Those companies I listed above usually provide the T/S parameters for their drivers. Each driver is different from the next so to model how it will perform we need those specifications. Se lets look at the 12" dayton DVC subwoofer driver. The T/S parameters are supplied in the description.

Specifications:

Diameter 12"

Power handling: 350 watts RMS/per coil, 700 watts max

Impedance: 8 Ohms

Frequency Response: 20-450 Hz

Sensitivity: 87.4 dB 1W/1m

Voice coil diameter: 2"

Magnet Weight: 112 oz

T/S Parameters

Resonant Frequency (Fs): 22.2 Hz

DC Resistance (Re): 2.8 ohms

Voice Coil Inductance (Le): 1.76 mH

Mechanical Q (Qms): 8.69

Electromagnetic Q (Qes): 0.4

Total Q (Qts) :0.38

Compliance Equivalent Volume (Vas): 4.25 ft.³

Mechanical Compliance of Suspension (Cms): 0.2 mm/N

BL Product (BL): 15.85 Tm

Diaphragm Mass Inc. Airload (Mms): 259.3g

Maximum Linear Excursion (Xmax): 15.1 mm

Surface Area of Cone (Sd): 502.7 cm²

Now you'll need to open winISD and we can start modeling an enclosure for that driver!

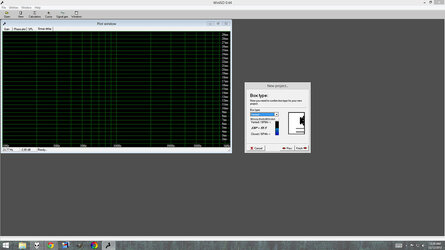

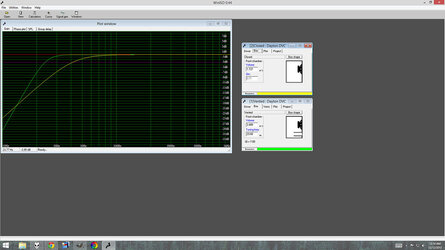

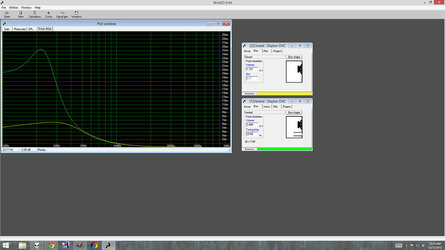

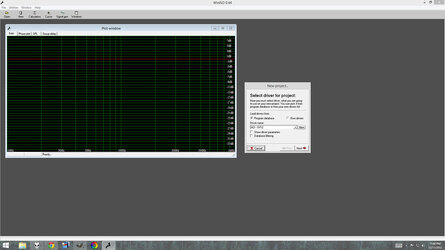

When you first open winISD you should get a screen like this.

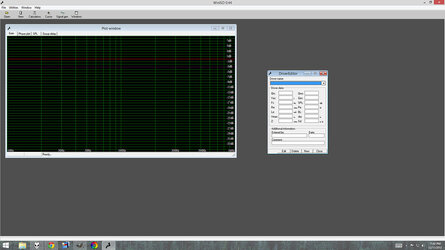

You will need to click on the New icon to start a new project. A new window should pop up like this.

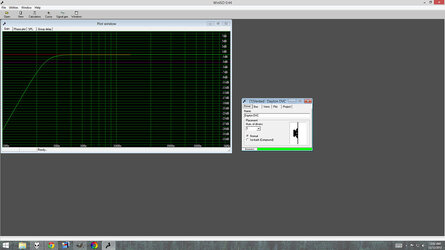

Next you will need to click the new button to the left of driver name to open the Driver Editor.

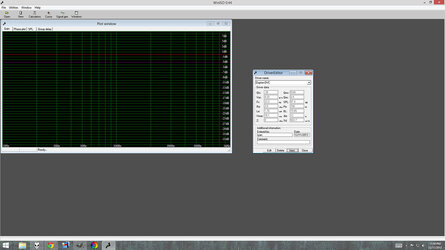

Now lets name the driver Dayton DVC (dont include numbers in the driver name. for some reason they wont get saved if there are nubmers in the title). Then fill in the Driver data boxes with the correct value as givien for that specific driver. Sometimes you need to set winISD to the proper measurement system. For instance Vas will usually be measured in liters or cubic ft. To change winISD Just click the mouse over the measurement system to the right of the box and click it until you get the correct measurement system.

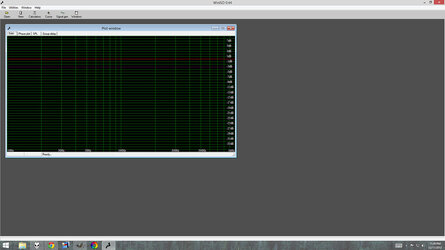

It should look like this when you are done.

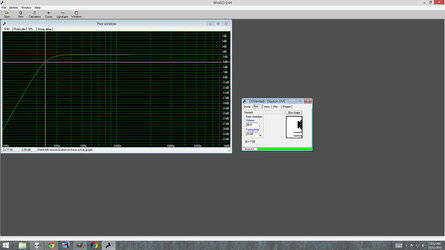

Sometimes you will not have a value like BL or Sd. Its usually ok since we are just modeling the enclosure. Once you have all the values filled in click the OK button and then Close. That will close out the window bringing you back to were you started.

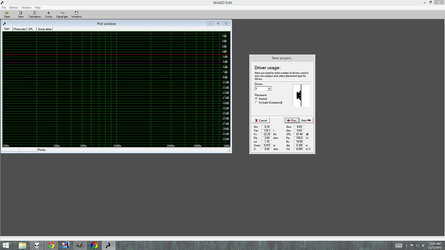

Now click new again. this time select the Own drivers under the Load drivers from: Also click the show driver parameters check box.

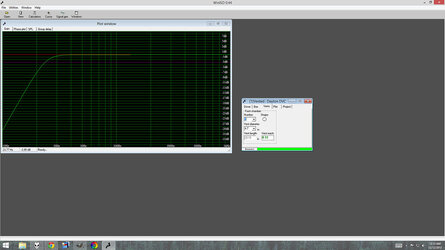

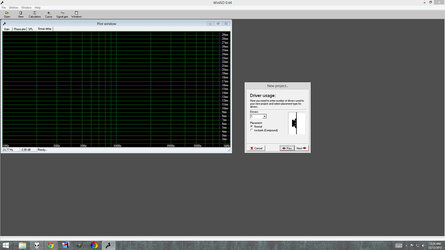

Now click next and it should bring you to the driver usage screen. Here you can select how many drivers to use and their configuration. We will be just using one driver and it wont be iso-barik so just hit next.

Continued------

Ok lets start off by explaining some of the basics. The audible frequencies range for humans is 20 to 20,000Hz. A subwoofer is a special speaker that handles all of the low bass frequencies in a sound system. They usually handle the frequencies from as high as 150 Hz and lower. This is a great page for seeing what instruments cover what frequency ranges http://www.psbspeakers.com/FrequenciesOfMusic.html.

A standard powered subwoofer is comprised of a few different parts. The main parts are the actually subwoofer driver, an enclosure for the driver, and amplifier, and a crossover.

I'll start with the driver first. The subwoofer driver is what reproduces the bass. Most subwoofers will use 10" or larger drivers to hit the lower bass notes. I will be using a Dayton DVC 12" subwoofer driver for the tutorial.

Now onto the enclosure. The enclosures purpose is to isolate the back wave of the subwoofer driver. There are several different ways to go about building an enclosure such as using sono tube (large diameter cardboard tube's) or the more traditional wood enclosure. There are also quite a few configurations ranging from sealed to passive radiator to ported etc. We will concentrate on only sealed and ported.

Now lets talk about amplifiers. There are largely two ways to go about powering your subwoofer. One way is to buy a plate amplifier designed for a subwoofer. The other is using a normal pro audio amplifier (you can use old stereo receivers etc but those are really not ideal solutions). The most convenient in my opinion is the plate amplifier option since it usually includes the crossover and mounts right in the speaker enclosure. It is most cost effective and should provide plenty of power for most subwoofers.

Then there is the crossover. The crossover separates the the frequencies so that the subwoofer doesn't receive any of the high frequency material. You can buy external crossovers or if you buy a plate amplifier it will usually have a crossover built in. Most subwoofers are crossed over at 100 hz or lower. Your actual crossover point you would use depends on your main speakers and the room the sound system is in.

Now that we have covered some of the basics lets start by setting a budget for the project. Most good subwoofers will cost around $200~300 minimum but it can be done for cheaper. once you have a budget set you can start seeing whats available around that price point. I would recommend looking at Parts Express, or madisound (I like their Dayton Audio DVC and Titanic series, as well as Tang band products but there are TONS of great options out there). As mentioned earlier I will be using a Dayton DVC 12" subwoofer for the tutorial.

They are a very good value for performance and can work well in larger or smaller enclosures. Once you have a driver selected you will need to get the T/S parameters do design the enclosure with winISD. This is a great page for learning about subwoofer design and they have a good explanation of T/S parameters etc. http://www.diysubwoofers.org/define.htm . Those companies I listed above usually provide the T/S parameters for their drivers. Each driver is different from the next so to model how it will perform we need those specifications. Se lets look at the 12" dayton DVC subwoofer driver. The T/S parameters are supplied in the description.

Specifications:

Diameter 12"

Power handling: 350 watts RMS/per coil, 700 watts max

Impedance: 8 Ohms

Frequency Response: 20-450 Hz

Sensitivity: 87.4 dB 1W/1m

Voice coil diameter: 2"

Magnet Weight: 112 oz

T/S Parameters

Resonant Frequency (Fs): 22.2 Hz

DC Resistance (Re): 2.8 ohms

Voice Coil Inductance (Le): 1.76 mH

Mechanical Q (Qms): 8.69

Electromagnetic Q (Qes): 0.4

Total Q (Qts) :0.38

Compliance Equivalent Volume (Vas): 4.25 ft.³

Mechanical Compliance of Suspension (Cms): 0.2 mm/N

BL Product (BL): 15.85 Tm

Diaphragm Mass Inc. Airload (Mms): 259.3g

Maximum Linear Excursion (Xmax): 15.1 mm

Surface Area of Cone (Sd): 502.7 cm²

Now you'll need to open winISD and we can start modeling an enclosure for that driver!

When you first open winISD you should get a screen like this.

You will need to click on the New icon to start a new project. A new window should pop up like this.

Next you will need to click the new button to the left of driver name to open the Driver Editor.

Now lets name the driver Dayton DVC (dont include numbers in the driver name. for some reason they wont get saved if there are nubmers in the title). Then fill in the Driver data boxes with the correct value as givien for that specific driver. Sometimes you need to set winISD to the proper measurement system. For instance Vas will usually be measured in liters or cubic ft. To change winISD Just click the mouse over the measurement system to the right of the box and click it until you get the correct measurement system.

It should look like this when you are done.

Sometimes you will not have a value like BL or Sd. Its usually ok since we are just modeling the enclosure. Once you have all the values filled in click the OK button and then Close. That will close out the window bringing you back to were you started.

Now click new again. this time select the Own drivers under the Load drivers from: Also click the show driver parameters check box.

Now click next and it should bring you to the driver usage screen. Here you can select how many drivers to use and their configuration. We will be just using one driver and it wont be iso-barik so just hit next.

Continued------

Last edited: