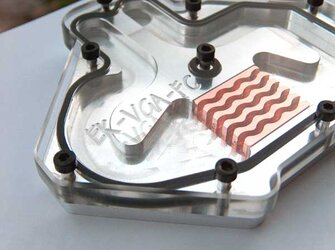

The idea for GF6800 WB came itself.

I like GeForces because of one-side placed rams and therefore I find it easyer to construct and make WB to cover the rams.

I got the inovatek WB few days ago in my hands and I took the distances between holes for mounting the WB.

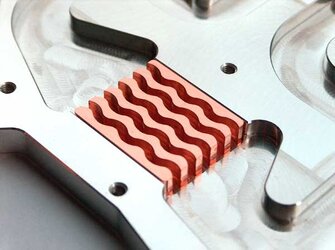

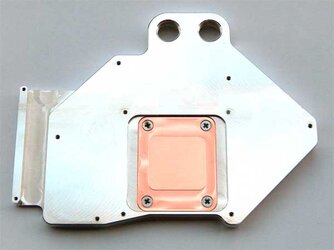

The concept of WB is that where the high preformance coling isn't needed (rams) I will use aluminium. And for GPU processor I will use copper. The combination of material is mostly for the weight reduction and easier to work with.

The aluminium part of the WB is (will be) eloxed or nickel plated, therefore there will bo no conflicts with copper. The silicon gasket is used for sealing between copper and aluminium. It is resistant on temperatures till 250°C.

The block weights 405 g.

Any comments

I like GeForces because of one-side placed rams and therefore I find it easyer to construct and make WB to cover the rams.

I got the inovatek WB few days ago in my hands and I took the distances between holes for mounting the WB.

The concept of WB is that where the high preformance coling isn't needed (rams) I will use aluminium. And for GPU processor I will use copper. The combination of material is mostly for the weight reduction and easier to work with.

The aluminium part of the WB is (will be) eloxed or nickel plated, therefore there will bo no conflicts with copper. The silicon gasket is used for sealing between copper and aluminium. It is resistant on temperatures till 250°C.

The block weights 405 g.

Any comments

Attachments

Last edited: