- Joined

- Apr 1, 2004

- Location

- Vancouver Canada

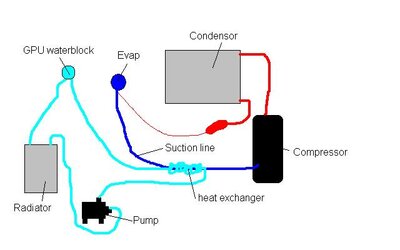

I have finally finnished brazing up my phase change unit. There is still tonnes of work to do on the powersupply, fans, wiring, case, chilled water loop etc, but the actual phase loop is up and running. I vacumed it and charged it up with crappy camping bottle propane just to see what it could do. I managed to get down to -47.6c.. not to shabby for a first build, but this is no load of course.

The system was running at 15" HG and 135psi. One thing I'm a bit confused about though, at 15" HG, the evap temperature of R290 is around -57, so where did my 10 degrees go? I had the temperature probe pressed on the bottom of the evap with some insulation over it, so it should have been pretty accurate.

The system uses a 1/2 hp rotary compressor, large AC unit condensor, 93" of 0.028 cap tube, home made evap and a SS flex line. Any of you propane guys have any advice? What sort of pressures do you run your systems at when they are on a cpu?

Anyway, here are some picks of the thing running.

The system was running at 15" HG and 135psi. One thing I'm a bit confused about though, at 15" HG, the evap temperature of R290 is around -57, so where did my 10 degrees go? I had the temperature probe pressed on the bottom of the evap with some insulation over it, so it should have been pretty accurate.

The system uses a 1/2 hp rotary compressor, large AC unit condensor, 93" of 0.028 cap tube, home made evap and a SS flex line. Any of you propane guys have any advice? What sort of pressures do you run your systems at when they are on a cpu?

Anyway, here are some picks of the thing running.