- Joined

- Mar 31, 2005

- Location

- Stealing your megahurtz at night

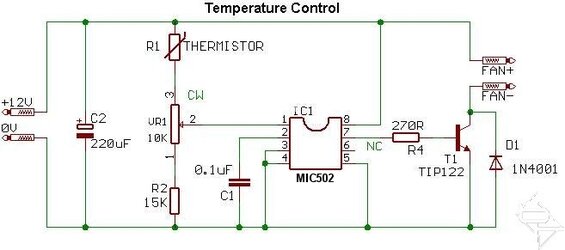

So I am looking for a way to make a fan controller that would automatically adjust fan speeds depending on temperatures. I had this idea the other day, because I am working on putting together a water cooling loop, and I don't really trust Speedfan to do it, and would rather just build something. I was looking at the guide above to make my own PWM fan controller, and thought to myself, instead of the Rheo, why not find a way to have it adjust automatically. If there is a way that I can solder some parts in that would allow me to set a temperature where the fan speed changes, even if by jumpers or changing out a resistor, diode, or whatever it might be, I would love to hear it. Chances are for the temp sensor, I will be using THIS. This will be controlling 3 120mm fans, which i would prefer to each have their own circuit. If there was a way that I could have it pass data on to the computer as well, that would be something interesting to add, but I don't know the first thing about writing any programs.