Costs me about a buck and a half, costs them probably twenty to fifty cents. Plus a little bit of PCB space.

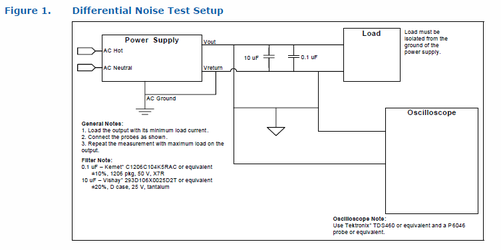

The issue is that if the transients are being generated

in the wires just before they leave the PSU case a capacitor on the PCB cannot get rid of them, the capacitor has to be between the source of the transients and the tester/device.

I know it doesn't make sense from a normal electrical theory standpoint, but high frequency electronics is

very different! What a SMPS unit does is akin to electrical voodoo, really.

(A similar mind bender: If you're running gigabit ethernet there is one bit of data per foot or so that exists only in the wire. It has been sent, and the transmitter is already sending other bits, but it hasn't gotten to the receiver yet. Using an eight foot cable? There's an entire byte of data on those wires! Weird, eh? Now think about the cable from your ISP over the mountains to their ISP

Electronics at high frequency is downright strange, really the entire universe is quite weird when you leave our normal scale. Sugar ants can pick up balls of water for instance)

I'll have to pop a junk PSU open and take out some of the filter caps and post the ripple shots, they should be pretty spectacular! There's already a

lot of filtering on most PSU's output rails. The good ones, at least.

On one PSU I tested I could change the ripple transients dramatically by pushing the output wires further into the PSU case or pulling them out a bit, the amount of wire inside the case is also the antenna for receiving the ripple, and radio type transmissions are very sensitive to antenna length. It blew my mind, really.