- Joined

- May 31, 2004

Hi,

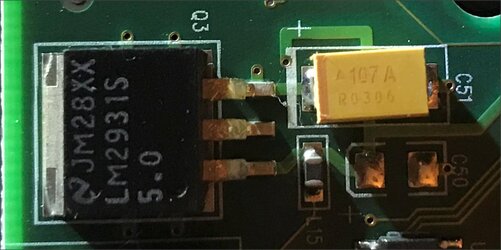

I need to replace a surface mounted capacitor and a surface mounted 12v to 5v converter. The latter is soldered to the board both at 3 legs and at its back which is soldered to a heat sink.

Do you have experience removing such devices? Can it be done with a soldering iron or do I need a hot air station? How can I heat the 12v converter without also damaging traces?

The pic shows the converter and capacitor that need to be replaced. The left side of the converter is soldered to a metal heat sink.

Thanks

I need to replace a surface mounted capacitor and a surface mounted 12v to 5v converter. The latter is soldered to the board both at 3 legs and at its back which is soldered to a heat sink.

Do you have experience removing such devices? Can it be done with a soldering iron or do I need a hot air station? How can I heat the 12v converter without also damaging traces?

The pic shows the converter and capacitor that need to be replaced. The left side of the converter is soldered to a metal heat sink.

Thanks