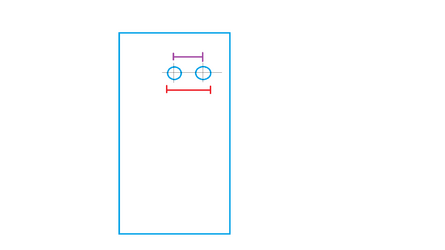

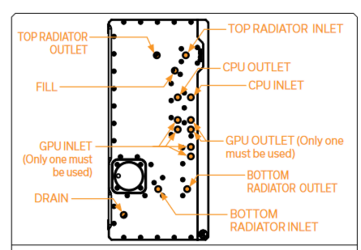

So the terminal on the GPU should have 4 openings. When the card is mounted horizontally (as depicted in your drawing) two will be on top, and two will be on the bottom of the terminal. We can call one front (closest to the distro plate) and one rear (closest to the IO plate of the card). Run the fluid into the bottom rear, and out of the top front, for example (I believe this is one of the more standard approaches and it is the one I use, as some blocks perform better using the rear as the inlet). The two unused holes should be plugged.

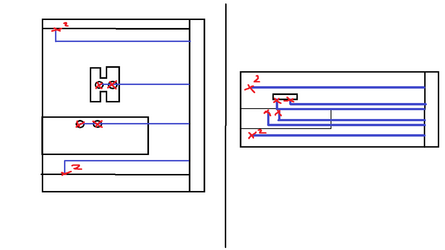

For the CPU, you'll want to either use spacers or a short tubing run up or uses spacers, such that as you look down upon the loop (changing your orientation in space from the previous example) such that the motherboard is the bottom, the tubes are stacked vertically on top of each other. Looking more closely at the new EK block, there isn't a middle inlet (they probably did this to accommodate abnormally large fittings, as you can see in the acrylic versions a little jog over to the middle pressure plate built into the block's intake). For AM4 it appears that the inlet must be towards the rear / IO side of the PC and the outlet towards the front / distribution block. In my drawing I had this reversed as one of your holes in your drawn block was close to the center of the block. With the inlet and outlet reversed from my drawing but in the stock EK configuration, the stacking of the hard tubing should make sense.

I'm not a hard tubing person myself, so apologies if this is unclear or I've said something stupid, but I think it should work this way. In your last post, what are we measuring? The distro plate? In this case it's going to be somewhat varied because I doubt a 90 fitting straight off the CPU block will make a straight shot to the distro plate in the first place, but for difference I would measure middle to middle, but some of this you're going to have to mock up to figure out IMHO (at least that's how I would do it). This is why buying a lot of extra fittings (especially 90 degree rotaries and extensions) is recommended so you don't have to order parts on trial and error. I know they're expensive but so is the rest of this hobby