- Joined

- Jan 27, 2006

hey all. I'm a new water cooling user. 3 weeks ago got my loop up and running and i love it. temps are amazing and much quieter!!. i have my computer right next to me on a table. usually its on the floor next to my desk but i wanted to keep my eye on it for a few weeks just to be extra safe to make sure no leaks or anything. i tend to have OCD with a few things. if something is a little off or think its should not be, i kinda go nuts until i fix it or figure it out. i was taking a few pictures today and i noticed a 2 things.

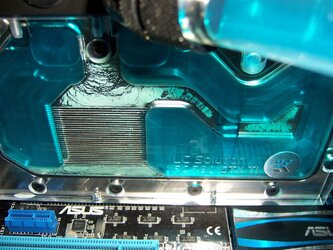

1st: was my video card block. in the area's were the bottom plexi and top meet seems to have a build up of something. not sure if its just because there is a VERY thin gap between where the two meet or what but there is this film in that area. i dont see it in my res, my cpu block, or tubes. just on my gpu block.

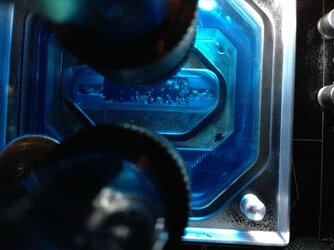

2nd: was looking close at my cpu and i noticed a few very small dots. looks like just gunk or build up? i have no idea. im afraid its build up from my coolant or dye. i only see it in the middle where the inlet is on the microchannels of the block.

its hard to get a picture of this because i dont have a good camera and its very close up. i took pictures with my crap 6 year old camera and iphone.

before i post pictures, here are the watercooling parts in my loop.

cpu block- EK-Supremacy Clean CSQ - Nickel + Plexi

VRM block-EK-MOSFET ASUS for Asus P8P67 Motherboards - Acetal-EN (Nickel)

gpu block- EK-FC780 GTX Ti - Nickel pelxi

res pump combo- EK-D5 Vario X-RES 140 (incl. pump)

rad 1- Alphacool NexXxoS ST30 Full Copper 240mm

rad 2- Alphacool NexXxoS XT45 Full Copper 360mm

tubing- PrimoFlex Advanced LRT 10ft Tubing - 3/8in. ID X 5/8in. OD - Crystal Clear

coolant- Mayhems X1 Coolant clear

dye- Mayhems Dye - 15ml Dark Blue

fittings- all bitspower black sparkle 3/8in. ID X 5/8in. OD

what i would like to know is what is this and what is causing it? will i be ok if i leave my loop how it is or would it be highly recommend to tear down my loop and clean this? i really dont want to tear down the loop and have a chance to screw something up when taking apart the blocks and re installing but if this is a serious issue i guess ill have to. i added about 10 drops of the mayhems dark blue dye. not sure if i added to much?

pictures:

Cpu: issue (hard to see with my crap pictures but look at the fin away of the inlet you'll see a few dark clumps (what is this and should i be ok ? if it stays like that and not more build up?)

GPU: see the film / dust, around the middle. some on the fin away but looks like its only at the top of the fins where they meet and touch the top of the plexi,

Extra pictures: here is picture of my complete build. not the best pictures just a few i took to give people an idea how my tubing looks as well as my water in my res. (forgive the mess of cables and my hanging SSD in the back.)

1st: was my video card block. in the area's were the bottom plexi and top meet seems to have a build up of something. not sure if its just because there is a VERY thin gap between where the two meet or what but there is this film in that area. i dont see it in my res, my cpu block, or tubes. just on my gpu block.

2nd: was looking close at my cpu and i noticed a few very small dots. looks like just gunk or build up? i have no idea. im afraid its build up from my coolant or dye. i only see it in the middle where the inlet is on the microchannels of the block.

its hard to get a picture of this because i dont have a good camera and its very close up. i took pictures with my crap 6 year old camera and iphone.

before i post pictures, here are the watercooling parts in my loop.

cpu block- EK-Supremacy Clean CSQ - Nickel + Plexi

VRM block-EK-MOSFET ASUS for Asus P8P67 Motherboards - Acetal-EN (Nickel)

gpu block- EK-FC780 GTX Ti - Nickel pelxi

res pump combo- EK-D5 Vario X-RES 140 (incl. pump)

rad 1- Alphacool NexXxoS ST30 Full Copper 240mm

rad 2- Alphacool NexXxoS XT45 Full Copper 360mm

tubing- PrimoFlex Advanced LRT 10ft Tubing - 3/8in. ID X 5/8in. OD - Crystal Clear

coolant- Mayhems X1 Coolant clear

dye- Mayhems Dye - 15ml Dark Blue

fittings- all bitspower black sparkle 3/8in. ID X 5/8in. OD

what i would like to know is what is this and what is causing it? will i be ok if i leave my loop how it is or would it be highly recommend to tear down my loop and clean this? i really dont want to tear down the loop and have a chance to screw something up when taking apart the blocks and re installing but if this is a serious issue i guess ill have to. i added about 10 drops of the mayhems dark blue dye. not sure if i added to much?

pictures:

Cpu: issue (hard to see with my crap pictures but look at the fin away of the inlet you'll see a few dark clumps (what is this and should i be ok ? if it stays like that and not more build up?)

GPU: see the film / dust, around the middle. some on the fin away but looks like its only at the top of the fins where they meet and touch the top of the plexi,

Extra pictures: here is picture of my complete build. not the best pictures just a few i took to give people an idea how my tubing looks as well as my water in my res. (forgive the mess of cables and my hanging SSD in the back.)

Last edited: