Hello,

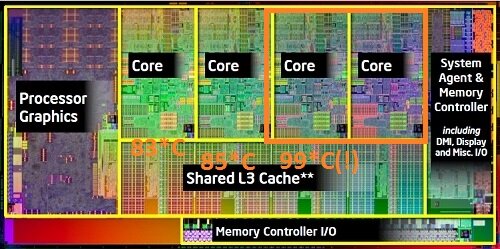

I am owner of i7-2920XM. It's currently set to run at 3.4 GHz. I have a big problem with it. If i repaste and reseat hetsink then temperatures under load are about 83-85C on 3800 MHz maximum on each core. After 1-2 months temperatures will differ much on Core 2 and Core 3. When Core0 has 83 then Core 2 has 97C or even 100C!). It only happens after a 1-2 months so the time matters. Im tired of constant repasting the CPU.

I replaced CPU fan (upgraded it) to high speed one. Also bought new thermal paste but it's still same, fine for 1-2 months then gets very hot. What can cause this? Heatsink defect or it's just CPU defect (I doubt it)?

I presume that it can be a bad heatsink. I can do the lapping, I have a machine to do this. I wonder if is there a way to check if heatsink is good or askew?

It's not important but laptop is Alienware M18xR1 with thriple-pipe CPU heatsink (XM) and highest speed 11.4 CFM Fan (XM)

Regards and waiting for your reply

I am owner of i7-2920XM. It's currently set to run at 3.4 GHz. I have a big problem with it. If i repaste and reseat hetsink then temperatures under load are about 83-85C on 3800 MHz maximum on each core. After 1-2 months temperatures will differ much on Core 2 and Core 3. When Core0 has 83 then Core 2 has 97C or even 100C!). It only happens after a 1-2 months so the time matters. Im tired of constant repasting the CPU.

I replaced CPU fan (upgraded it) to high speed one. Also bought new thermal paste but it's still same, fine for 1-2 months then gets very hot. What can cause this? Heatsink defect or it's just CPU defect (I doubt it)?

I presume that it can be a bad heatsink. I can do the lapping, I have a machine to do this. I wonder if is there a way to check if heatsink is good or askew?

It's not important but laptop is Alienware M18xR1 with thriple-pipe CPU heatsink (XM) and highest speed 11.4 CFM Fan (XM)

Regards and waiting for your reply