- Joined

- Feb 16, 2008

- Location

- East Coast

Topcc (who benched his ES 4770k and ES 3770k and published accurate results before NDA was up on either), also posted his IVY E ES 4960X showing small performance gain over Sandy E on same forum and was quoted on techpowerup...

http://www.techpowerup.com/183176/c...ghly-10-faster-than-i7-3970x-early-tests.html

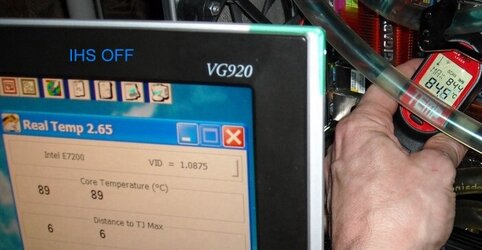

Then, after being incorrectly told by some on internet his IVY E 4960X had paste tim, despite no mention of temp issues, he delidded it. Though after cutting adhesive, he then had to use a heat gun (realizing it was likely soldered at that point) and pry it apart, ended up killing his cpu...then lot of cussing. but can clearly see solder on his dead cpu...

http://translate.google.com/transla...E8%84%82-%E8%B6%95%E7%BE%9A%E7%BE%8A%E5%8B%92

http://www.techpowerup.com/183176/c...ghly-10-faster-than-i7-3970x-early-tests.html

Then, after being incorrectly told by some on internet his IVY E 4960X had paste tim, despite no mention of temp issues, he delidded it. Though after cutting adhesive, he then had to use a heat gun (realizing it was likely soldered at that point) and pry it apart, ended up killing his cpu...then lot of cussing. but can clearly see solder on his dead cpu...

http://translate.google.com/transla...E8%84%82-%E8%B6%95%E7%BE%9A%E7%BE%8A%E5%8B%92