- Joined

- Mar 15, 2016

- Location

- Brisbane, Australia

I haven’t been able to find any helpful posts on large volume reservoirs, particularly for my recent build, so I thought I would post this to help someone in my position in the future. My first was 15 years with a 20lt plastic container with a pump in the container. My current build is a pump/waterblock combination into a radiator in a 30lt plastic bin, sitting in a 55lt metal bin.

What?

A large volume reservoir is a system that transfers the heat into a liquid filled container either by recycling all the liquid or with a closed loop that runs into it. The reservoir is a heat sink eliminating the need for fans. The container with the reservoir will also radiate heat, so never gets hot enough to overheat the CPU. It is designed for computers that aren’t run 24/7, with the volume of the reservoir being at least 20lt.

Why?

No fans, nice and quiet with no quick temperature increases of the water due to load. It is also simple and cheap. Best cooling possible for certain applications.

Why not?

A large container of water in your house, which could leak, and it takes up space. Not for 24/7 use, but in a cold climate with a big enough container it should work. Looks horrible!!

Parts for current build:

Apogee Drive II integrated pump & waterblock

2 fan radiator (could have used single fan)

3 metres of hose

7 fittings

Irrigation elbows (to create low point, so coolant drains into bucket and not computer if there is a leak at CPU)

30 litre plastic bin (to stop corrosion between radiator and bin)

55 litre metal bin (outside radiator)

Tube of silicon (to seal seams of bin – yes, it did leak)

4 litre bucket (for coolant leak collection)

1lt of coolant

Problems:

RAM radiator fin had to be trimmed to fit water block.

750w power supply would shut down when pump connected, so used another computer power supply - currently powering car sub as well.

Metal bin leaked, sealed with silicon.

Radiator was placed in metal bin and stripped galvanising off a section of bin overnight, so radiator moved into plastic bin. (Yes, I feel stupid now; a copper radiator in a metal bin…)

Performance:

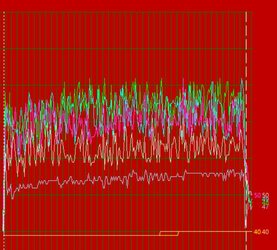

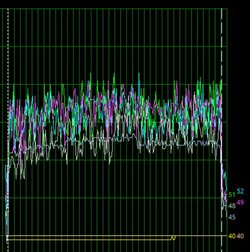

Excellent. The only purpose is for a DAW program to reduce the ASIO driver load from 100% with audio glitches. The cooling improved ASIO 100% to 95%, with overclocking down to 65%.

4770K (1.2 v, 100 x 44.0) runs at 35 to 40 C with minimal use, and during 100% load testing around 70 C. Current weather min 20 C, max 31 C.

After 9 hours of continual use with CPU at around 30%, the water in the plastic container is bath warm, with the metal bin water much cooler. The water cools to room temperature in less than 2 hours.

ASUS Fan Master reduced the pump speed to minimal, so it is never heard at any CPU load.

Next time:

I will use poly irrigation pipe similar to solar heating for pools in a metal container.

What?

A large volume reservoir is a system that transfers the heat into a liquid filled container either by recycling all the liquid or with a closed loop that runs into it. The reservoir is a heat sink eliminating the need for fans. The container with the reservoir will also radiate heat, so never gets hot enough to overheat the CPU. It is designed for computers that aren’t run 24/7, with the volume of the reservoir being at least 20lt.

Why?

No fans, nice and quiet with no quick temperature increases of the water due to load. It is also simple and cheap. Best cooling possible for certain applications.

Why not?

A large container of water in your house, which could leak, and it takes up space. Not for 24/7 use, but in a cold climate with a big enough container it should work. Looks horrible!!

Parts for current build:

Apogee Drive II integrated pump & waterblock

2 fan radiator (could have used single fan)

3 metres of hose

7 fittings

Irrigation elbows (to create low point, so coolant drains into bucket and not computer if there is a leak at CPU)

30 litre plastic bin (to stop corrosion between radiator and bin)

55 litre metal bin (outside radiator)

Tube of silicon (to seal seams of bin – yes, it did leak)

4 litre bucket (for coolant leak collection)

1lt of coolant

Problems:

RAM radiator fin had to be trimmed to fit water block.

750w power supply would shut down when pump connected, so used another computer power supply - currently powering car sub as well.

Metal bin leaked, sealed with silicon.

Radiator was placed in metal bin and stripped galvanising off a section of bin overnight, so radiator moved into plastic bin. (Yes, I feel stupid now; a copper radiator in a metal bin…)

Performance:

Excellent. The only purpose is for a DAW program to reduce the ASIO driver load from 100% with audio glitches. The cooling improved ASIO 100% to 95%, with overclocking down to 65%.

4770K (1.2 v, 100 x 44.0) runs at 35 to 40 C with minimal use, and during 100% load testing around 70 C. Current weather min 20 C, max 31 C.

After 9 hours of continual use with CPU at around 30%, the water in the plastic container is bath warm, with the metal bin water much cooler. The water cools to room temperature in less than 2 hours.

ASUS Fan Master reduced the pump speed to minimal, so it is never heard at any CPU load.

Next time:

I will use poly irrigation pipe similar to solar heating for pools in a metal container.