- Joined

- Jan 4, 2009

- Location

- Brandon Mississippi

Okay, so, two things happened today. I got my contacts (I can see!!!) and i lapped my CPU and my DK. Here's the story!

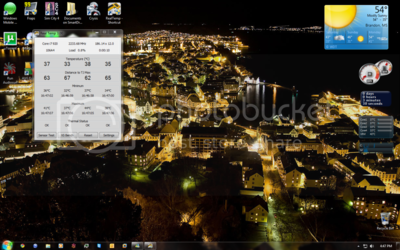

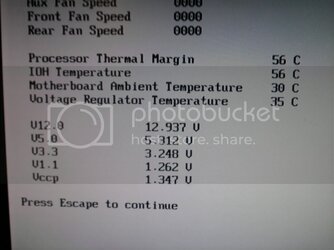

Before temps:

This is at 3.9. I think i did lower the voltage some between now and then, but it didn't impact temps all that much. I was still seeing 99C spikes when the heater came on. (it blows right into the front of my computer :/)

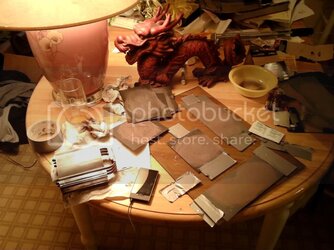

So, on to the lapping. I went between the CPU and DK. I'd get bored with one, and lap the other some, then get bored with it, and lap the other, ect ect.

After 10minutes or so on the CPU:

Already i know this may take a while...

After about a half hour...

Hour and a half...

I don't really know how long now... lol

That little spot on the bottom about drove me out of my mind...

Still working on the spot...

Okay, enough of the CPU.

After 20 minutes or so on the DK

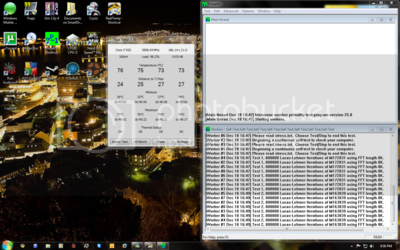

Before temps:

This is at 3.9. I think i did lower the voltage some between now and then, but it didn't impact temps all that much. I was still seeing 99C spikes when the heater came on. (it blows right into the front of my computer :/)

So, on to the lapping. I went between the CPU and DK. I'd get bored with one, and lap the other some, then get bored with it, and lap the other, ect ect.

After 10minutes or so on the CPU:

Already i know this may take a while...

After about a half hour...

Hour and a half...

I don't really know how long now... lol

That little spot on the bottom about drove me out of my mind...

Still working on the spot...

Okay, enough of the CPU.

After 20 minutes or so on the DK

Last edited: