- Thread Starter

- #81

mailed out more samples today should be up to date.

Going to ask you guys to extend burn in or cure time to see if we missed something (this is why we do these tests)

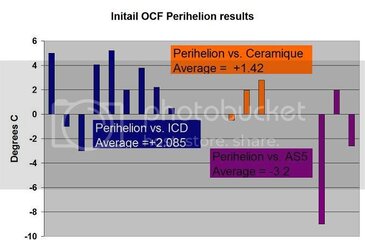

Some tests run on a PC test bed with a lab sample versus packed tube sample and we were surprised to see a burn in time of 4 days. Mix is similar to ICD with lower viscosity so running more tests along side yours to see what's up.

Thermal conductivity: 4.4 W/mK

Sample Thermal Impedance (deg C/W) Avg. CPU Temp.

(ICD) 0.009 64 C

Perihelion (lab sample) 0.012 67 C

Perihelion1 (sample syringe) 0.014 66C (after about 2 hours)

Perihelion (sample syringe) 0.012 60C (after about 4 days)

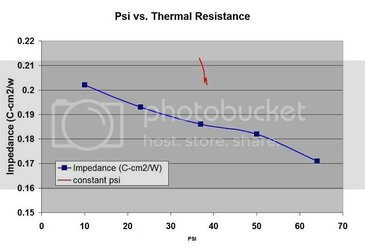

Thermal impedance as a function of pressure @ 120 Watts, 60 C:

@ 10 psi: 0.202 oC-cm2/W

23 psi: 0.193 oC-cm2/W

37 psi: 0.186 oC-cm2/W

50 psi: 0.182 oC-cm2/W

64 psi: 0.171 oC-cm2/W

Going to ask you guys to extend burn in or cure time to see if we missed something (this is why we do these tests)

Some tests run on a PC test bed with a lab sample versus packed tube sample and we were surprised to see a burn in time of 4 days. Mix is similar to ICD with lower viscosity so running more tests along side yours to see what's up.

Thermal conductivity: 4.4 W/mK

Sample Thermal Impedance (deg C/W) Avg. CPU Temp.

(ICD) 0.009 64 C

Perihelion (lab sample) 0.012 67 C

Perihelion1 (sample syringe) 0.014 66C (after about 2 hours)

Perihelion (sample syringe) 0.012 60C (after about 4 days)

Thermal impedance as a function of pressure @ 120 Watts, 60 C:

@ 10 psi: 0.202 oC-cm2/W

23 psi: 0.193 oC-cm2/W

37 psi: 0.186 oC-cm2/W

50 psi: 0.182 oC-cm2/W

64 psi: 0.171 oC-cm2/W