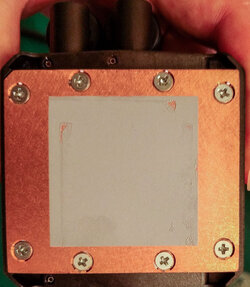

While install Corsair H60 AIO liquid coolor to Core i7 6700k cpu. I accidently touched the bottom of the water pump and left a fingerprint on the pre-applied thermal compound. I also noticed I chipped/scratched off several tiny blocks of the thermal compound on the heatsink. Please see picture here. The water pump hasn't touched the CPU's IHS yet so CPU there is no residue on the CPU. Do I need to wipe the heatsink clean completely and re-apply thermal compound on CPU ? or I can just contiune installation with current condition?

My goal is to run CPU cool and quiet for 5~7 years without ever needing to re-open the case after installation (which I do not enjoy to do). I haven't decided if I will overclock 6700k yet although I have asrock Z170 mITX board, ripjaw v 2x16GB 2400MHz DDR4, MSI GTX 1070 Gaming X 8G, Samsung 950 Pro 256GB M.2 PCIe x4 and 4x512GB 2.5" 850 Evo SSD @ raid 5 and corsair sfx 600w psu.

My main concern is there will be some air gaps in the affected spots between the CPU and pump/heatsink. But I also saw videos on youtube that the thermal compound will spreadout evenly after applying force during the mounting process. That's why I halfed my installation until I received some advices from experts. I don't have extra thermal compound on hand right now. Thanks!!!

My goal is to run CPU cool and quiet for 5~7 years without ever needing to re-open the case after installation (which I do not enjoy to do). I haven't decided if I will overclock 6700k yet although I have asrock Z170 mITX board, ripjaw v 2x16GB 2400MHz DDR4, MSI GTX 1070 Gaming X 8G, Samsung 950 Pro 256GB M.2 PCIe x4 and 4x512GB 2.5" 850 Evo SSD @ raid 5 and corsair sfx 600w psu.

My main concern is there will be some air gaps in the affected spots between the CPU and pump/heatsink. But I also saw videos on youtube that the thermal compound will spreadout evenly after applying force during the mounting process. That's why I halfed my installation until I received some advices from experts. I don't have extra thermal compound on hand right now. Thanks!!!