- Joined

- Jun 17, 2010

- Location

- Marietta, GA

Modding LEDs into a Fan

Alright, so I've mentioned a couple times to a couple people that you don't have to sacrifice performance for looks when it comes to fans. You can have great fans and you can have them lit up like Christmas, they don't have to be mutually exclusive. There are a couple things that I should say up front. First off, I've never actually done this mod (just writing the guide because it comes up so much...), but I've seen it done and am 100% sure it will work. Second, I don't know if this slightly degrades fan performance, I could see it if it worked out either way. Third, this may add a slightly turbulent sound to your fan, it hasn't, but it could...do it right and it shouldn't. Fourth, this mod will not make your fans look like the ones that light up the casing and everything, they'll look like antec tricools, where only the blades are lit up.

Alright, on to the fun stuff. There are a couple things you'll need for this mod 1)a drill 2)some perfboard 3)some resistors (all the same value, all matched to your LEDs) 4)some LEDs 5)a fan you want to mod 6)soldering iron 7)solder 8)wire 9)molex connector (optional). This list isn't exactly complete, but its most of what you'll need, sorry for the stuff I missed.

The first thing you need to do is drill holes for your LEDs. To select the correct drill bit, line up the LED with the bit and look down it, you should be able to see the flared base but not the main body of the LED, that way you know that the LED will not get lost in the hole. Drilling angle of the holes is crucial for achieving the right look. You want to space the holes equally and drill each hole so that the LED points midway between the edge of the casing and the hub, right at the middle of the blades. Make sure you don't hit the blades with the drill (you can remove them if you feel so compelled) and make sure that the LEDs fit in the holes. You want the edge of the bulb right on the edge of the casing (but not protruding much, if at all), because of this, you may have to come back with a larger bit and create a lip for the flared bottom of the LED to rest on (make sure this bit is larger than the lip). With this done, you can secure your LEDs into their newly made sockets (superglue and jb weld are fantastic for this, I couldn't get hot glue to work nor could I get modeling cement to work, just make sure you can get at the leads and that the leads are not touching, its probably a good idea not to fully secure them in until you've hooked them up to the perfboard).

The second bit might be a little tricky if you haven't had some soldering experience, and I strongly suggest you learn how to solder before you go about this, it's not a difficult project at all, but you want it to last, so knowing how to solder the right way is vital. You can use any LED you want for this so long as it is 2 lead, the multicolor and odd colored ones won't work with this circuit because they have multiple leads. On your molex from your PSU, you will see 4 wires, the middle 2 are black, these are both ground, the other 2 are yellow and red, the yellow carries +12vdc and the red carries +5vdc. So that this project is fully compatible with any LED (I don't know of any that go over 5, but god knows there'll be one of you out there who finds one ), I've designed the circuit to be powered from the yellow wire. You will need one resistor for each LED you use, if the LEDs are different (multicolored fans or different colored fans) make sure that you get the right value for each one or you can burn out your LEDs virtually instantly. To calculate your required resistor value is quite easy, you take your source voltage (12v) and subtract the voltage the LED requires (lets call it 3v) and then divide by the maximum current the LED will handle

This is your minimum resistor value, anything from here up to about 1k ohm should work, the best way to be sure it will work is to get the first standard value above the number you calculate (so if you calculate 338 ohms, a 335 ohm resistor won't work, but a 340 ohm resistor will). Put the resistors through the board parallel to each other (not wired in parallel, just next to each other, there's an easy way to wire them in parallel, that's coming). Strip a piece of wire and put it through so that it's on the bottom of the board and runs at least as many holes as the number of LEDs you have, this should be oriented perpendicular to your resistors. Solder the resistors all to this. Run the yellow wire from the molex (you can do this with a male to female molex connector if you don't want to cut the end of your cable off) to the board and solder it to the stripped piece of wire as well. This is your +12v rail. Now you need to run wiring to the LEDs. Something like speaker wire would work well for this since you can go up and back in a nice compact package (long ribbon cables are the best if you can find them, but they're not exactly common anymore), any sort of coax is a good alternative to speaker wire. Solder the wire to the other lead of the resistor and then solder that same wire to the long lead (anode) of the capacitor. If the leads are the same length you need to solder it to the side that isn't notched/flattened. Lets review:

), I've designed the circuit to be powered from the yellow wire. You will need one resistor for each LED you use, if the LEDs are different (multicolored fans or different colored fans) make sure that you get the right value for each one or you can burn out your LEDs virtually instantly. To calculate your required resistor value is quite easy, you take your source voltage (12v) and subtract the voltage the LED requires (lets call it 3v) and then divide by the maximum current the LED will handle

This is your minimum resistor value, anything from here up to about 1k ohm should work, the best way to be sure it will work is to get the first standard value above the number you calculate (so if you calculate 338 ohms, a 335 ohm resistor won't work, but a 340 ohm resistor will). Put the resistors through the board parallel to each other (not wired in parallel, just next to each other, there's an easy way to wire them in parallel, that's coming). Strip a piece of wire and put it through so that it's on the bottom of the board and runs at least as many holes as the number of LEDs you have, this should be oriented perpendicular to your resistors. Solder the resistors all to this. Run the yellow wire from the molex (you can do this with a male to female molex connector if you don't want to cut the end of your cable off) to the board and solder it to the stripped piece of wire as well. This is your +12v rail. Now you need to run wiring to the LEDs. Something like speaker wire would work well for this since you can go up and back in a nice compact package (long ribbon cables are the best if you can find them, but they're not exactly common anymore), any sort of coax is a good alternative to speaker wire. Solder the wire to the other lead of the resistor and then solder that same wire to the long lead (anode) of the capacitor. If the leads are the same length you need to solder it to the side that isn't notched/flattened. Lets review:

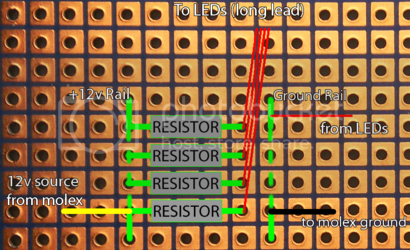

Make sure you don't mess that up or the LED will not power on. Connect the other lead to another wire and run it back to the board. Rinse repeat for all your LEDs, and if you're using multiple types, make sure the right resistor gets to the right LED. Strip another piece of wire and run it through the board perpendicular to the LEDs, just like the first one but on the other side. Solder all of the wires returning from the LEDs to this. Now solder a black lead from the molex (one of the middle 2) to the stripped wire as well, this is your ground rail and your LEDs should now be ready for operation. The below image should help you visualize all of this.

the dashed lines are to represent a wire under the board

A few things to consider having finished this:

1)Insulate the perfboard - this can be as simple as wrapping it in electrical tape or as complicated as potting it (where you put it in a mould and blow in an insulating substance that hardens around it)

2)Make sure there is LITERALLY no way any of the wires could cross - expose as little wire as possible and be careful

3)Setup your common ground at the fan - you can connect all the short leads of the LEDs and then just run one wire to the fan from the molex ground if you're going for a really really low profile

4)Mount the perfboard - you can drill it and run bolts through it or whatever, just make sure you don't hit your circuitry

5)If you're running all the same LEDs, you can actually use just 1 resistor and cut down on space big time...I don't wholly recommend this, but I'll give you the formula anyways

6)Red LEDs tend to be dimmer than blue ones - if you're planning on using red LEDs you may want to consider using more of them than if you were using blue, 5 reds should work for a 120 imo

7)Ultrabright LEDs FTW - the LEDs must shine as far as possible into the blades of the fan for the most even lighting, it will never really be truly even, but ultrabrights and good spacing can help this.

Hopefully this helps some people not have to sacrifice performance for looks. The total cost for this is quite low, but if you have to buy the parts from somewhere like RadioShack, you'll end up paying a good bit. The alternative to this is somewhere like mouser, but there you'll pay $7 shipping. Price everything out and see how you can do it cheapest (it shouldn't be much more than $10, the more LEDs you do, the less you pay per LED, so one big build for all your fans is the best way to keep costs down).

PEACE! Post some pics and suggestions if you do this, hope it helps!

EDIT: My comments are after the dash, I'll be integrating suggestions and comments here so that it's a single post that people can be referred to rather than a thread they have to read through and pick the relevant comments out of

from neonblingbling:

1)You can flatten the face of the LED with a dremel sanding drum to increase diffusion of light and allow less of the LED to protrude from the fan housing - just be careful that you don't hit the innards, they're pretty easy to see

2)Solder at the base of the LED so that you're less likely to break the leads. - I should have mentioned this but I've done it for long enough that it didn't even cross my mind. Once you know anode from cathode you can clip your leads and leave as little showing as possible. If you ever need to determine anode from cathode after you've clipped the leads (lets say you're resoldering it or something) you can look through the plastic and see what looks like a flag, the lead connected to this is the cathode, the other one is the anode

Alright, so I've mentioned a couple times to a couple people that you don't have to sacrifice performance for looks when it comes to fans. You can have great fans and you can have them lit up like Christmas, they don't have to be mutually exclusive. There are a couple things that I should say up front. First off, I've never actually done this mod (just writing the guide because it comes up so much...), but I've seen it done and am 100% sure it will work. Second, I don't know if this slightly degrades fan performance, I could see it if it worked out either way. Third, this may add a slightly turbulent sound to your fan, it hasn't, but it could...do it right and it shouldn't. Fourth, this mod will not make your fans look like the ones that light up the casing and everything, they'll look like antec tricools, where only the blades are lit up.

Alright, on to the fun stuff. There are a couple things you'll need for this mod 1)a drill 2)some perfboard 3)some resistors (all the same value, all matched to your LEDs) 4)some LEDs 5)a fan you want to mod 6)soldering iron 7)solder 8)wire 9)molex connector (optional). This list isn't exactly complete, but its most of what you'll need, sorry for the stuff I missed.

The first thing you need to do is drill holes for your LEDs. To select the correct drill bit, line up the LED with the bit and look down it, you should be able to see the flared base but not the main body of the LED, that way you know that the LED will not get lost in the hole. Drilling angle of the holes is crucial for achieving the right look. You want to space the holes equally and drill each hole so that the LED points midway between the edge of the casing and the hub, right at the middle of the blades. Make sure you don't hit the blades with the drill (you can remove them if you feel so compelled) and make sure that the LEDs fit in the holes. You want the edge of the bulb right on the edge of the casing (but not protruding much, if at all), because of this, you may have to come back with a larger bit and create a lip for the flared bottom of the LED to rest on (make sure this bit is larger than the lip). With this done, you can secure your LEDs into their newly made sockets (superglue and jb weld are fantastic for this, I couldn't get hot glue to work nor could I get modeling cement to work, just make sure you can get at the leads and that the leads are not touching, its probably a good idea not to fully secure them in until you've hooked them up to the perfboard).

The second bit might be a little tricky if you haven't had some soldering experience, and I strongly suggest you learn how to solder before you go about this, it's not a difficult project at all, but you want it to last, so knowing how to solder the right way is vital. You can use any LED you want for this so long as it is 2 lead, the multicolor and odd colored ones won't work with this circuit because they have multiple leads. On your molex from your PSU, you will see 4 wires, the middle 2 are black, these are both ground, the other 2 are yellow and red, the yellow carries +12vdc and the red carries +5vdc. So that this project is fully compatible with any LED (I don't know of any that go over 5, but god knows there'll be one of you out there who finds one

Code:

(V[sub]s[/sub]-V[sub]L[/sub])/I

V[sub]s[/sub] = Source Voltage

V[sub]L[/sub] = LED Voltage

I = current

Code:

notch/flatside/short lead = cathode = negative voltage

rounded side/long lead = anode = positive voltage

the dashed lines are to represent a wire under the board

A few things to consider having finished this:

1)Insulate the perfboard - this can be as simple as wrapping it in electrical tape or as complicated as potting it (where you put it in a mould and blow in an insulating substance that hardens around it)

2)Make sure there is LITERALLY no way any of the wires could cross - expose as little wire as possible and be careful

3)Setup your common ground at the fan - you can connect all the short leads of the LEDs and then just run one wire to the fan from the molex ground if you're going for a really really low profile

4)Mount the perfboard - you can drill it and run bolts through it or whatever, just make sure you don't hit your circuitry

5)If you're running all the same LEDs, you can actually use just 1 resistor and cut down on space big time...I don't wholly recommend this, but I'll give you the formula anyways

Code:

(V[sub]s[/sub]-V[sub]L[/sub])/I[sub]T[/sub]

V[sub]s[/sub] = Source Voltage

V[sub]L[/sub] = LED Voltage (for 1 LED)

I[sub]T[/sub] = current of one LED x number of LEDs you're using7)Ultrabright LEDs FTW - the LEDs must shine as far as possible into the blades of the fan for the most even lighting, it will never really be truly even, but ultrabrights and good spacing can help this.

Hopefully this helps some people not have to sacrifice performance for looks. The total cost for this is quite low, but if you have to buy the parts from somewhere like RadioShack, you'll end up paying a good bit. The alternative to this is somewhere like mouser, but there you'll pay $7 shipping. Price everything out and see how you can do it cheapest (it shouldn't be much more than $10, the more LEDs you do, the less you pay per LED, so one big build for all your fans is the best way to keep costs down).

PEACE! Post some pics and suggestions if you do this, hope it helps!

EDIT: My comments are after the dash, I'll be integrating suggestions and comments here so that it's a single post that people can be referred to rather than a thread they have to read through and pick the relevant comments out of

from neonblingbling:

1)You can flatten the face of the LED with a dremel sanding drum to increase diffusion of light and allow less of the LED to protrude from the fan housing - just be careful that you don't hit the innards, they're pretty easy to see

2)Solder at the base of the LED so that you're less likely to break the leads. - I should have mentioned this but I've done it for long enough that it didn't even cross my mind. Once you know anode from cathode you can clip your leads and leave as little showing as possible. If you ever need to determine anode from cathode after you've clipped the leads (lets say you're resoldering it or something) you can look through the plastic and see what looks like a flag, the lead connected to this is the cathode, the other one is the anode

Last edited: