At 10c I doubt he will have a major issue with freezing but he will see condensation issues though. If freezing is an issue remember a water/ methanol mix should not exceed a 50/50 mix and check your o-rings for comparability. If running a water/glycol mix you better make sure your pump will be able to handle the increased viscosity of the mixture at sub-zero temperatures. This becomes extremely important to maintain a large flow rate over the radiator so as to avoid localized freezing effects.

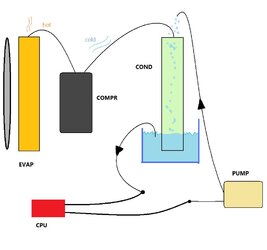

What I continue to struggle with is why we are trying to "Re-invent" what has already been done. There is plenty of people that have run a phase change unit too cool a laid loop before but the complications of this system make it infeasible for most. Also if you are going to go this route you would do better with a more traditional heat exchange cooling plate versus a radiator floating in a bucket of water.

If you want to go sub-zero why not just run a full phase change unit mounted to the cpu?

I can understand the need that water modularity would offer a system running multiple gpu/cpu in a benching rig but if you want to do sub-zero you really need to get your setup designed right and have the right chemical mixture in the water loop to avoid freezing.

If you are only trying to go sub ambient I go back to my normal stance that the benefits you gain by going from 22c water to 10c water are negligible when compared against the hassle of condensation and a phase change setup.

If we are talking purely something for benching/testing or just for giggles I am all good. Heck I have used everything from LN2 poured into a water/methanol loop all the way down to a radiator floating in a water bath cooled by frozen produce inn an effort to achieve above normal clock speeds. In doing all of this I can't argue that they were effective, but i have never once suffered from the delusion that these methods would be good for the masses much less more efficient than traditional, properly designed and executed cooling methods.