Hey guys, I got sick of this maze3 in my puter. so I decided to make a simple block, hoping to outperform it by only a little if any. I just want something nice in there.

This is my first block with an o-ring and I would have to say the O-ring groove is successful! Im leaktesting it right now and all is well

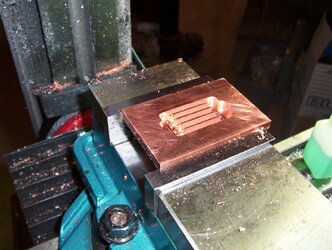

the channels are 1/8" and fins are 1/16" in a 7/8" wide total size. The standard 1/2" barbs. There is only one other block with the same material used for the top, and both were made by me. Ill keep that on the DL though and if you know, please keep it to yourself.

and if you know, please keep it to yourself.

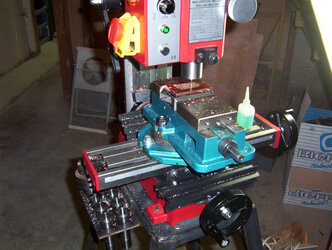

First 4 pics are the base being milled. The last 3 are the completed work.

Enjoy

Jon

This is my first block with an o-ring and I would have to say the O-ring groove is successful! Im leaktesting it right now and all is well

the channels are 1/8" and fins are 1/16" in a 7/8" wide total size. The standard 1/2" barbs. There is only one other block with the same material used for the top, and both were made by me. Ill keep that on the DL though

First 4 pics are the base being milled. The last 3 are the completed work.

Enjoy

Jon