I currently have what I consider a pretty good AIO, a corsair i150 pro 360. I bought it 4 years ago for my Ryzen 7 3700x (yes I know an overkill, but above all I wanted a quiet pc and it fulfilled that need marvellously).

However, needs change, and I've recently explored overclocking a ryzen 9 5950x at various powers up to 250W and recently I've upgraded to am5 ryzen 9 7950x which if overclocked can be pushed over 300W I believe. (BTW I use arctic mx-6 paste.)

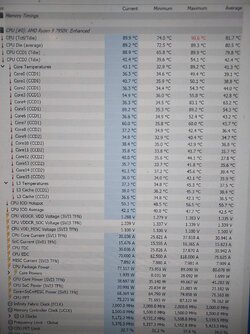

When oc'ing 5950x I noticed a kind of a "brick wall" somewhere around 230W with my aio (once it reaches steady state). Until that power level temperature scales with increases in power, but definitely below a 1 to 1 ratio. For example at 225W I could keep my cpu at 83C(water temp around 36C, room temp about 21C). At 235W it very quickly reaches towards 90C. The water temperature is the same. So I have to assume the bottleneck in heat transfer is somewhere between the die, the ihs, the cold plate and the fin stack. Not the radiator.

Ryzen 9 7950x has a smaller ihs and I suspect this might be a reason why I see this very quick increase to even 95C at even lower power of 170W (no OC).

So I started researching custom loops (just for the cpu for now). And there is very conflicting info out there. There are videos that show 1C of difference at 230~300W power levels. And 15C difference at 350W(although on Intel).

Is it really possible to achieve 15C extra difference in temperatures in a custom loop at around 350W considering the radiator is essentially the same size and tubing thickness impact is negligible(as demonstrated elsewhere on this forum)?

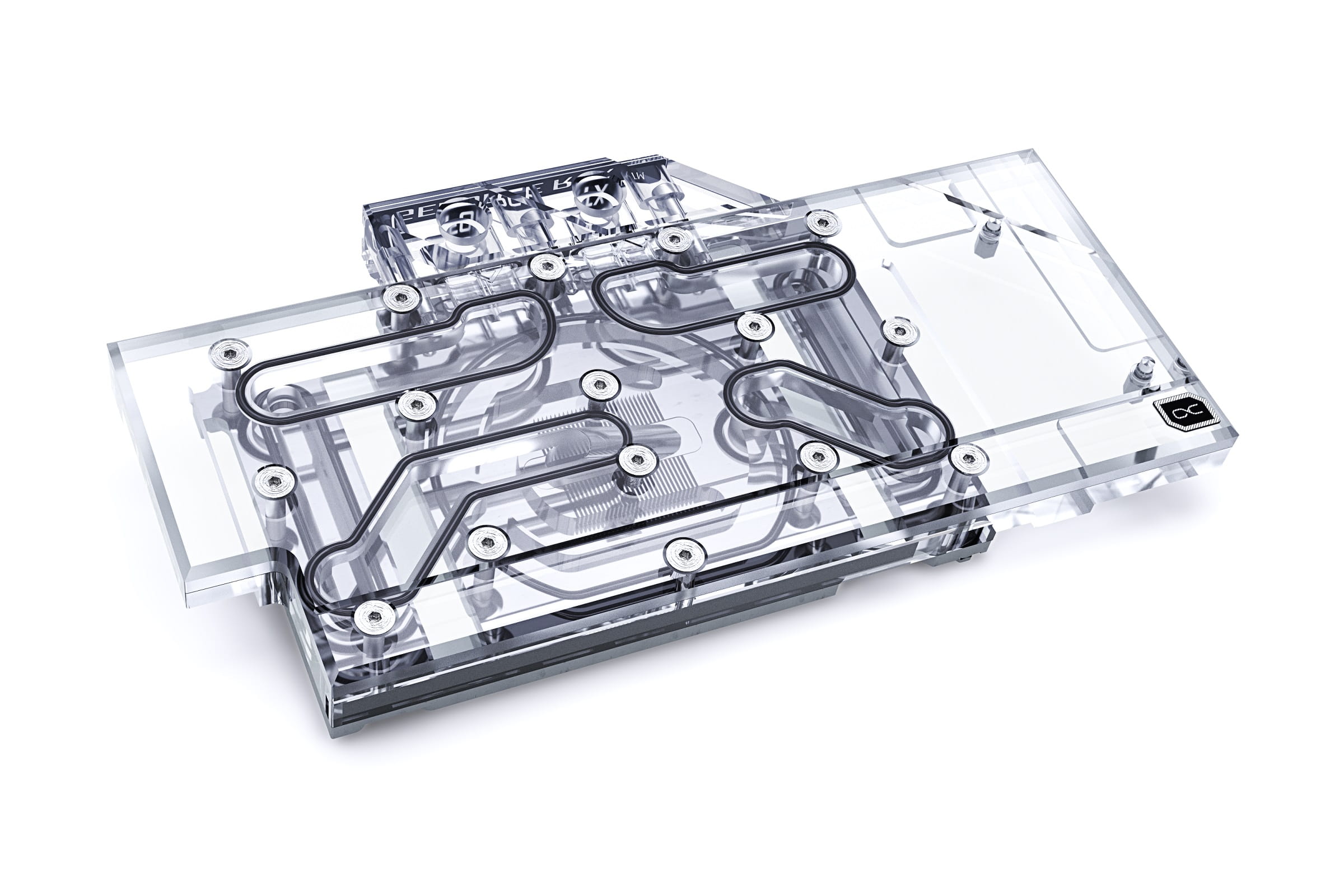

The only real difference IMO between a good AIO and a custom loop seems to be water amount being pushed through the fin stack (due to much more powerful pump) and the height of the fin stack on the cold plate. Please note I'm not that interested in a brief advantage a custom loop can give you due to higher water volume available, but a steady state operation.

So in summary, has anyone replaced a 360mm AIO with a custom loop on a 350W CPU? What happened to your temps? What were the water temps before and after?

I have to admit I'm very surprised the water never gets hotter than 36.4C while the cores are 95C,but perhaps that's just the heat transfer across the ihs? Idk.

However, needs change, and I've recently explored overclocking a ryzen 9 5950x at various powers up to 250W and recently I've upgraded to am5 ryzen 9 7950x which if overclocked can be pushed over 300W I believe. (BTW I use arctic mx-6 paste.)

When oc'ing 5950x I noticed a kind of a "brick wall" somewhere around 230W with my aio (once it reaches steady state). Until that power level temperature scales with increases in power, but definitely below a 1 to 1 ratio. For example at 225W I could keep my cpu at 83C(water temp around 36C, room temp about 21C). At 235W it very quickly reaches towards 90C. The water temperature is the same. So I have to assume the bottleneck in heat transfer is somewhere between the die, the ihs, the cold plate and the fin stack. Not the radiator.

Ryzen 9 7950x has a smaller ihs and I suspect this might be a reason why I see this very quick increase to even 95C at even lower power of 170W (no OC).

So I started researching custom loops (just for the cpu for now). And there is very conflicting info out there. There are videos that show 1C of difference at 230~300W power levels. And 15C difference at 350W(although on Intel).

Is it really possible to achieve 15C extra difference in temperatures in a custom loop at around 350W considering the radiator is essentially the same size and tubing thickness impact is negligible(as demonstrated elsewhere on this forum)?

The only real difference IMO between a good AIO and a custom loop seems to be water amount being pushed through the fin stack (due to much more powerful pump) and the height of the fin stack on the cold plate. Please note I'm not that interested in a brief advantage a custom loop can give you due to higher water volume available, but a steady state operation.

So in summary, has anyone replaced a 360mm AIO with a custom loop on a 350W CPU? What happened to your temps? What were the water temps before and after?

I have to admit I'm very surprised the water never gets hotter than 36.4C while the cores are 95C,but perhaps that's just the heat transfer across the ihs? Idk.