-

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

de-Lid the IB chip

- Thread starter Jpaul

- Start date

- Joined

- Apr 6, 2012

- Location

- Wichita, KS

Ivy Bridge chips are clock for clock a few percentage points faster than Sandy Bridge chips and have significantly lower TDPs. They do get hotter when overvolting and overclocking due to a different design.

- Joined

- Mar 12, 2002

Its not strictly necessary to delid an Ivy but if your pushing for the highest possible clockspeeds it will help. How much depends on your chip some people report ~5C drop others up to ~20C drop. Either way even without delidding it the Ivys can go pretty darn far. If your already on Sandy Bridge though its really not worth upgrading.

- Joined

- Jul 29, 2011

- Location

- Buenos Aires, Argentina

20c drops are 100% normal, except for very good contact between die and ihs from the factory. You see lesser drops cause people do it wrong or use the wrong tim for the die.

Liquid metal paste on die will produce more than 10c temp drops when pushing a decent overclock that is. You won't see a 20c improvement if you're running stock clocks or a 4.2 oc!

Liquid metal paste on die will produce more than 10c temp drops when pushing a decent overclock that is. You won't see a 20c improvement if you're running stock clocks or a 4.2 oc!

- Joined

- Jul 29, 2011

- Location

- Buenos Aires, Argentina

Nope, it does make a big difference when using the same tim...But liquid metal tim has a really high w/mk value which translates into a much better ability to conduct heat in smaller surface areas (like a die)

I have Liquid metal on my gpu die atm and it runs REALLY cool, despite being a reference design EVGA cooler...I got a 15c drop compared to the stock tim.

I can post some before and after results from a thread in OCN too...

I have Liquid metal on my gpu die atm and it runs REALLY cool, despite being a reference design EVGA cooler...I got a 15c drop compared to the stock tim.

I can post some before and after results from a thread in OCN too...

- Joined

- Jul 29, 2011

- Location

- Buenos Aires, Argentina

Yeah I know, but I have first hand experience on the matter...and know plenty of people that do too.

Here's the thread...

There's a spreadsheet with results and tons of screenshots.

Here's the thread...

There's a spreadsheet with results and tons of screenshots.

Thanks... but my point is while the TIM method replacement may help, shortening the distance between IHS and the core help more. There is a thread Im still trying to find on this that was posted here....

I still dont see point in this for normal users. Hell, Im not a normal user and wont do it..!

EDIT: Found it -> http://www.overclockers.com/forums/showthread.php?t=721089

I still dont see point in this for normal users. Hell, Im not a normal user and wont do it..!

EDIT: Found it -> http://www.overclockers.com/forums/showthread.php?t=721089

- Joined

- Jul 29, 2011

- Location

- Buenos Aires, Argentina

If you got a really hot chip and want to run 5ghz 24/7 and don't plan on benching it's pretty cool.

You gotta do them both, remove the glue and use liquid metal tim on die, pretty simple really.

And do the cut in a single motion, and ALSO be extra careful when putting the chip in the socket cause you can wreck your socket like I did. (the ihs will move then you press the latch and bend pins, which will result in a burnt socket or chip like mine)

The proper way to do it is:

-Use a thin gillette type razor, do a single motion cut around the die, under the ihs carefully avoiding nicking the pcb or hitting the die.

-Press the ihs in place with your finger while closing the latch to keep the chip in place in the socket.

Bingo!

EDIT: Intel could have gotten a MASSIVE success with IB if they chose to use liquid metal tim on the die, cause it stays put and doesn't pump out like regular tims do, and if they glued the ihs' more carefully, without massive goops of glue.

You gotta do them both, remove the glue and use liquid metal tim on die, pretty simple really.

And do the cut in a single motion, and ALSO be extra careful when putting the chip in the socket cause you can wreck your socket like I did. (the ihs will move then you press the latch and bend pins, which will result in a burnt socket or chip like mine)

The proper way to do it is:

-Use a thin gillette type razor, do a single motion cut around the die, under the ihs carefully avoiding nicking the pcb or hitting the die.

-Press the ihs in place with your finger while closing the latch to keep the chip in place in the socket.

Bingo!

EDIT: Intel could have gotten a MASSIVE success with IB if they chose to use liquid metal tim on the die, cause it stays put and doesn't pump out like regular tims do, and if they glued the ihs' more carefully, without massive goops of glue.

- Joined

- Jul 29, 2011

- Location

- Buenos Aires, Argentina

Cool!

Max oc and volts?

Max oc and volts?

- Joined

- Aug 1, 2012

- Location

- Minneapolis, MN

I still dont see point in this for normal users. Hell, Im not a normal user and wont do it..!

I agree, not worth it for a normal user. And I've done 2 of them now. Saw 20C drop in full load temps both times (actually 21 on 1 and 19 on the other). I did it because I like to play around, well, and I don't like to listen to fans.

Personally, I think the problem is a COMBINATION of the TIM and the IHS distance from the die. At his point though, I can't prove it either way.

You have to weigh the pros and cons. I'd say the cons outweigh the pros.

Pro - cooler temps

Cons - relatively high risk (damaged pins, mangled processor, etc), you'll never sell the chip

Of course, there are others, but those are the big ones.

EDIT: My apples to apples comparison here: http://www.overclockers.com/forums/showpost.php?p=7366147&postcount=26

Last edited:

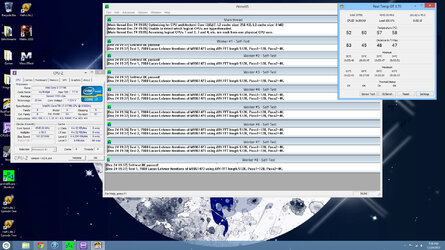

Cool! But tough to compare apples to apples with different clockspeeds and voltages... but it is clear you did see notable improvement.So far max stable is 4.8 with 1.4 volts and a max temp of 91C with a H100

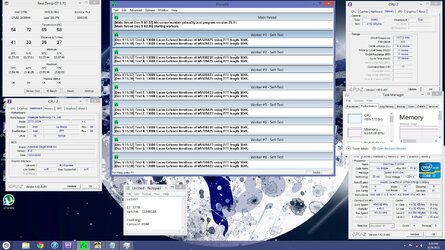

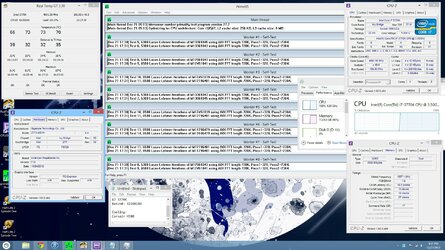

Before

After

Also, if you use the non GT .exe of Realtemp, you wont have space there for two other cores (GT was made for Gulftown iirc, hence the space for 6 cores).

- Joined

- Oct 14, 2012

Cool! But tough to compare apples to apples with different clockspeeds and voltages... but it is clear you did see notable improvement.

Also, if you use the non GT .exe of Realtemp, you wont have space there for two other cores (GT was made for Gulftown iirc, hence the space for 6 cores).

Here's one with the same voltage and speed, although the H100 is in a push setup vs push/pull as before.

de-liding it and adding liquid metal can drop 15'C-20'C at the 5.0'Ghz zone

result is you can push another 200-300Mhz (reported) on the clock. Not for gamers, stricting for crazying benching folks only. Voiding the warranty is one thing, I have read people seeing problems 2-3 months down the road cause they likely damaged the chip in the processs.

I did 1 chip, and so far so good, but I dont recommend this for anyone, unless they are ready to lose everything in the process and understands the risk.

FYI, in my case, I was able to get 100Mhz out of it with increase voltage without temp raises. I was hoping to get 200Mhz outta it, but didn't happen for me.

result is you can push another 200-300Mhz (reported) on the clock. Not for gamers, stricting for crazying benching folks only. Voiding the warranty is one thing, I have read people seeing problems 2-3 months down the road cause they likely damaged the chip in the processs.

I did 1 chip, and so far so good, but I dont recommend this for anyone, unless they are ready to lose everything in the process and understands the risk.

FYI, in my case, I was able to get 100Mhz out of it with increase voltage without temp raises. I was hoping to get 200Mhz outta it, but didn't happen for me.

Last edited:

Similar threads

- Replies

- 4

- Views

- 2K