- Joined

- May 7, 2005

im going to rerun the tubing in my back up rig with hardline. ive never used it before so im looking for your advice. i have lots of questions for you pros out there!

i know from reading through others posts that its best to stick with the same manny for tubing and fittings. so ill stick with xspx gear if possible. is it a good idea to go with xspc gear? their stuff is cheap in comparison to other gear so i hope so lol.

so i hope so lol.

1. is this xspx kit any good? is there something better i should go with? ive heard that having a really good tool to round off the ends of your tubing is a must if you dont want to ruin your gaskets. is the one that comes with this kit any good?

http://www.performance-pcs.com/xspc-petg-easy-cut-easy-bend-toolkit.html

2. is xspc petg tubing good stuff? is it easy to work with? is there a better brand for a first timer to use? is there a specific size i want to look for rather than 14-10? friggin hate that there isnt a standard unit of measurement. trying to make sure everything matches up is a pita!

http://www.performance-pcs.com/xspc-petg-tubing-14-10mm-2-x-50cm-pack-clear.html

3. are xspc hardline fittings good? if not please advise. will likely go with the black ones rather than black chrome(black/white theme) but i dont see any 45 or 90s in black grrrr.

http://www.performance-pcs.com/xspc-g1-4-to-14-10mm-petg-triple-seal-black-chrome-8-pack.html

4. should i go with this heatgun?

http://www.performance-pcs.com/monsoon-hardline-pro-heatgun-kit.html

5. is there anything else im overlooking? i dont want to have to make any catch up orders if at all possible.

thats all i can think of right now.

thanks in advance!

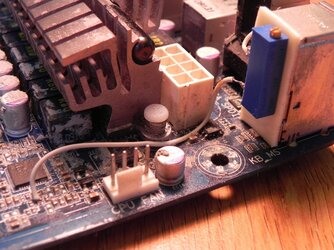

edit- another thing. im replacing the ddc pump connectors and wires with a 4pin pwm connection(no more molex) should i leave the molex? is it ok to replace it? meaning will it have enough juice to start up and run with the 4pin pwm only? is 18awg wire what im looking for? and should i go with 1/8in sleeving or 1/4in sleeving for that?

i know from reading through others posts that its best to stick with the same manny for tubing and fittings. so ill stick with xspx gear if possible. is it a good idea to go with xspc gear? their stuff is cheap in comparison to other gear

1. is this xspx kit any good? is there something better i should go with? ive heard that having a really good tool to round off the ends of your tubing is a must if you dont want to ruin your gaskets. is the one that comes with this kit any good?

http://www.performance-pcs.com/xspc-petg-easy-cut-easy-bend-toolkit.html

2. is xspc petg tubing good stuff? is it easy to work with? is there a better brand for a first timer to use? is there a specific size i want to look for rather than 14-10? friggin hate that there isnt a standard unit of measurement. trying to make sure everything matches up is a pita!

http://www.performance-pcs.com/xspc-petg-tubing-14-10mm-2-x-50cm-pack-clear.html

3. are xspc hardline fittings good? if not please advise. will likely go with the black ones rather than black chrome(black/white theme) but i dont see any 45 or 90s in black grrrr.

http://www.performance-pcs.com/xspc-g1-4-to-14-10mm-petg-triple-seal-black-chrome-8-pack.html

4. should i go with this heatgun?

http://www.performance-pcs.com/monsoon-hardline-pro-heatgun-kit.html

5. is there anything else im overlooking? i dont want to have to make any catch up orders if at all possible.

thats all i can think of right now.

thanks in advance!

edit- another thing. im replacing the ddc pump connectors and wires with a 4pin pwm connection(no more molex) should i leave the molex? is it ok to replace it? meaning will it have enough juice to start up and run with the 4pin pwm only? is 18awg wire what im looking for? and should i go with 1/8in sleeving or 1/4in sleeving for that?

Last edited: