- Joined

- Dec 7, 2003

- Thread Starter

- #101

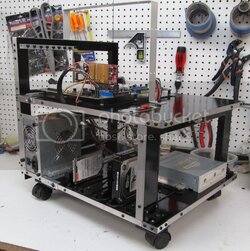

Station#28--the SR-2 project

And here is another new version. Somebody wanted a station to accommodate an SR-2 motherboard.

The SR-2 is a giant unique "HTPX" motherboard for dual 1366 sockets:

Official EVGA SR-2 motherboard link.

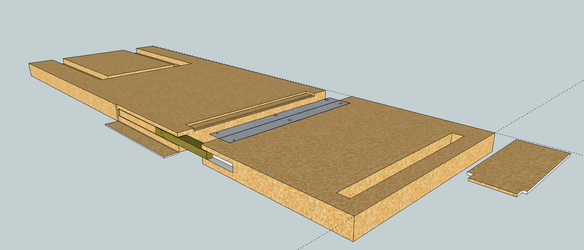

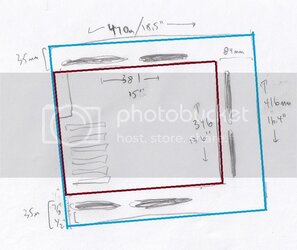

I first started with a general size layout sketch:

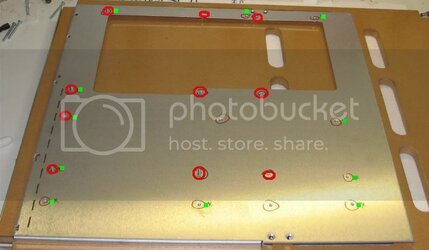

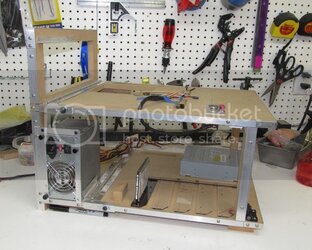

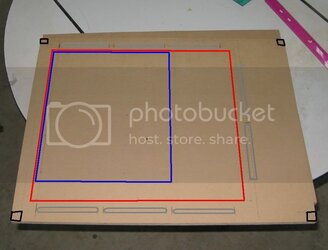

Then I cut my plates:

The purple represents a standard ATX motherboard, the red the SR-2.

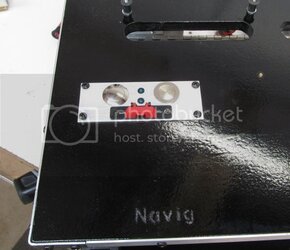

Next I milled out the cable passthrus:

Note, that this station will accommodate a standard motherboard or an SR-2.

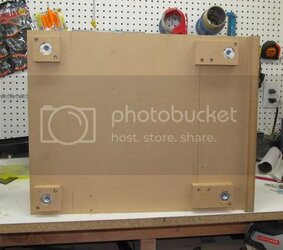

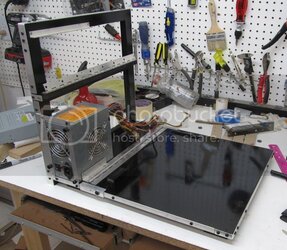

Paint:

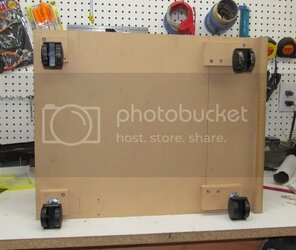

Parts:

.

And here is another new version. Somebody wanted a station to accommodate an SR-2 motherboard.

The SR-2 is a giant unique "HTPX" motherboard for dual 1366 sockets:

Official EVGA SR-2 motherboard link.

I first started with a general size layout sketch:

Then I cut my plates:

The purple represents a standard ATX motherboard, the red the SR-2.

Next I milled out the cable passthrus:

Note, that this station will accommodate a standard motherboard or an SR-2.

Paint:

Parts:

.