Hello,

Mark here...it's been forever since I was here last.

I recently purchased an ASUS Crosshair V Formula Z (AM3+) as an update for my even older motherboard in my Linux Mint box.

All jibes aside, I have a pre-build question or three.

Before taking it apart, does anyone recall if the VRM coolers on this MB use paste, putty or tape in the OEM build?

If it's putty or tape, I should probably update it anyway because of technology changes.

If it's paste, then it will need a good cleaning and some more modern paste.

I'd just like a clue before I get into it. I do like the mounting configuration, the backing plates were a great idea.

Next question:

It's kind of a cooler/motherboard thing.

i purchased a used Scythe Mungen 5 cooler and it was in more or less pristine condition, packed in the original box with all components.

However, looking at the contact surface on the heat block, there was a rather deep radial moire pattern that defied conventional wisdom concerning these surfaces. The flattest surfaces reflected a severely warped image of my window blinds, like looking into a funhouse mirror.

Upon running a diamond lapping flat that I have over the surface a few times, I discovered that the center was high like an island. There was a depression around this point with the edges seemingly at the same height as the center. Think like an impact crater. I was well through the nickel plating in the center, before the depression plating was ever touched. The entire difference would have been about two or three times the nickel plating thickness, if not a little more. I've already taken it down to flat and just need to make sure there are no rough spots. I'm not going for a mirror finish.

Here's the deal. Could this have been a unit that missed a final flattening operation before plating? The reason I ask is this particular heatsink was tested on a number of websites, one of which actually rated and compared the contact surface to Noctua and a half dozen others, as being the most consistently flat in the current marketplace.

If this surface was never "finished", it might explain why I've been having a devil of a time getting the heatsink attached to the mounting plates on the motherboard. The screws do not reach and it requires an inordinate amount of "elbow grease" to even get the screws to touch. Clearly, warping the motherboard would be required. I have temporarily abated this problem by putting some thin washers under the Mounting Plates that raises them about 0.003". With the washers in place, the screws just make contact with the plates and I can tighten them without distressing the motherboard, while still achieving excellent contact force. After mounting half a dozen CM Hyper 212 EVO's, my Nocuta NH-D15 and some other similar mounts, I've never had a problem like this or had to resort to DIY methods to get the things to mount.

Last question:

Has anyone else experienced these kinds of issues with either Scythe or other brands?

Thanks all for your patience, wisdom and willingness to consider my ramblings.

Mark

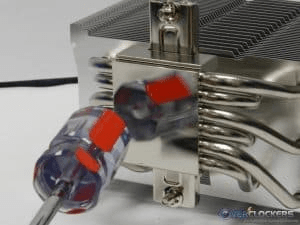

Image from overclockers.com Mungen 5 Rev B review September 20, 2019 by Matthew Green

This is not what my surface would have reflected, it would have been a smeared radial blur.

Mark here...it's been forever since I was here last.

I recently purchased an ASUS Crosshair V Formula Z (AM3+) as an update for my even older motherboard in my Linux Mint box.

All jibes aside, I have a pre-build question or three.

Before taking it apart, does anyone recall if the VRM coolers on this MB use paste, putty or tape in the OEM build?

If it's putty or tape, I should probably update it anyway because of technology changes.

If it's paste, then it will need a good cleaning and some more modern paste.

I'd just like a clue before I get into it. I do like the mounting configuration, the backing plates were a great idea.

Next question:

It's kind of a cooler/motherboard thing.

i purchased a used Scythe Mungen 5 cooler and it was in more or less pristine condition, packed in the original box with all components.

However, looking at the contact surface on the heat block, there was a rather deep radial moire pattern that defied conventional wisdom concerning these surfaces. The flattest surfaces reflected a severely warped image of my window blinds, like looking into a funhouse mirror.

Upon running a diamond lapping flat that I have over the surface a few times, I discovered that the center was high like an island. There was a depression around this point with the edges seemingly at the same height as the center. Think like an impact crater. I was well through the nickel plating in the center, before the depression plating was ever touched. The entire difference would have been about two or three times the nickel plating thickness, if not a little more. I've already taken it down to flat and just need to make sure there are no rough spots. I'm not going for a mirror finish.

Here's the deal. Could this have been a unit that missed a final flattening operation before plating? The reason I ask is this particular heatsink was tested on a number of websites, one of which actually rated and compared the contact surface to Noctua and a half dozen others, as being the most consistently flat in the current marketplace.

If this surface was never "finished", it might explain why I've been having a devil of a time getting the heatsink attached to the mounting plates on the motherboard. The screws do not reach and it requires an inordinate amount of "elbow grease" to even get the screws to touch. Clearly, warping the motherboard would be required. I have temporarily abated this problem by putting some thin washers under the Mounting Plates that raises them about 0.003". With the washers in place, the screws just make contact with the plates and I can tighten them without distressing the motherboard, while still achieving excellent contact force. After mounting half a dozen CM Hyper 212 EVO's, my Nocuta NH-D15 and some other similar mounts, I've never had a problem like this or had to resort to DIY methods to get the things to mount.

Last question:

Has anyone else experienced these kinds of issues with either Scythe or other brands?

Thanks all for your patience, wisdom and willingness to consider my ramblings.

Mark

Image from overclockers.com Mungen 5 Rev B review September 20, 2019 by Matthew Green

This is not what my surface would have reflected, it would have been a smeared radial blur.