- Joined

- Jun 17, 2003

- Location

- Maryland, USA

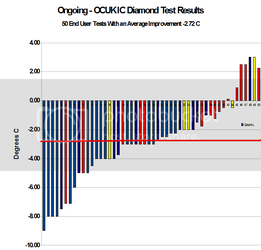

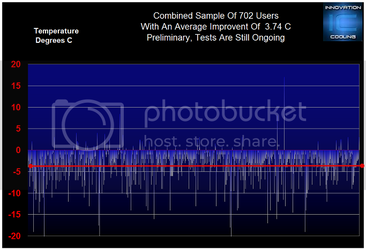

My turn. This is _way_ overdue, but I am glad to finally share my unscientific conclusion: ICD7 is better than AS Matrix or AS5. Just get it.

I am wrapping up a build an i7 950 @3.8 on air w/HT with ICD7, and am getting ~-3C below AS Matrix and ~-6C below AS5 in controlled conditions (same ambient, voltages, speeds, etc,) running Intel Burn Test, then Rosetta@Home.

With an ambient of 24C, using Real Temp, the avg is low-mid 70s with ICD7 vs mid-high 70s with AS Matrix, vs high 70s to low 80s with AS5. I will admit the AS5 isn't fully broken in though. This is with an Arctic Freezer Pro7 rev2 at full speed, board sitting on top of a static bad that's reflecting heat back onto the board. I am sure my temps will drop slightly when this is in the case. And if this was high end air or water, the temps would be stellar.

Thanks for the tube, Joe. My only regrets are not using this sooner, and not keeping up my end of the bargain sooner!

I am wrapping up a build an i7 950 @3.8 on air w/HT with ICD7, and am getting ~-3C below AS Matrix and ~-6C below AS5 in controlled conditions (same ambient, voltages, speeds, etc,) running Intel Burn Test, then Rosetta@Home.

With an ambient of 24C, using Real Temp, the avg is low-mid 70s with ICD7 vs mid-high 70s with AS Matrix, vs high 70s to low 80s with AS5. I will admit the AS5 isn't fully broken in though. This is with an Arctic Freezer Pro7 rev2 at full speed, board sitting on top of a static bad that's reflecting heat back onto the board. I am sure my temps will drop slightly when this is in the case. And if this was high end air or water, the temps would be stellar.

Thanks for the tube, Joe. My only regrets are not using this sooner, and not keeping up my end of the bargain sooner!