- Joined

- Nov 6, 2003

- Location

- Denver, CO

The other day I was dreaming about owning a Porsche 911 Turbo with the XD50 power package. That thing is amazing, it gets 450 HP and a similar amount of torque out of a 3.6liter motor.

Then it hit me! Twin turbo's. Well, metaphorically speaking, if this was in car terms, you guys with your Thermalright SP-97's would be like a big block v8, and my volcano9 like a 3.6 liter flat 6. Why not make mine a a twin turbo?

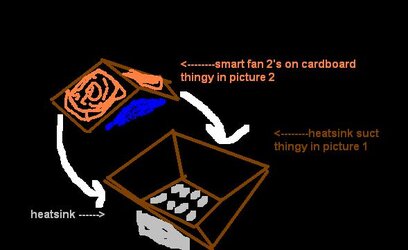

Ok....here is the thing....I decided to try and lower my temperatures by ramming more air through my heat sink. A Thermal Take Smart Fan2 on full blast was not enough, so why not put 2 on?

Here is how I did it.

*WARNING this material is rated "restricted" or "R" for those who hate ghetto looking projects or lowering their temps for free*

MATERIALS NEEDED

STAGE 1

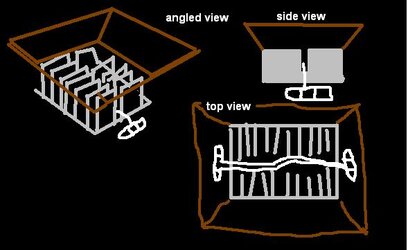

In this first picture you will see this shroud thing I built out of cardboard. I just cut out pieces of cardboard, not entirely square as you can see. I taped these 4 pieces together and probably made an opening of a good 100-150mm above my heat sink. I kind of made a fan adapter, but this is only stage one. At this point, I did not have it on the heat sink. This does not have to be perfect, the pieces I cut out were less than symmetrical . The gaps can just be fixed with tape. I just used standard masking tape.

. The gaps can just be fixed with tape. I just used standard masking tape.

Then it hit me! Twin turbo's. Well, metaphorically speaking, if this was in car terms, you guys with your Thermalright SP-97's would be like a big block v8, and my volcano9 like a 3.6 liter flat 6. Why not make mine a a twin turbo?

Ok....here is the thing....I decided to try and lower my temperatures by ramming more air through my heat sink. A Thermal Take Smart Fan2 on full blast was not enough, so why not put 2 on?

Here is how I did it.

*WARNING this material is rated "restricted" or "R" for those who hate ghetto looking projects or lowering their temps for free*

MATERIALS NEEDED

- Masking tape. ALLOT of it

- Cardboard, box, approximately 1-2 square feet needed

- box cutter

- 2 fans that you plan to use

- Elmer's school glue

- hair dryer (optional, it just helps you dry the glue faster)

- patience

STAGE 1

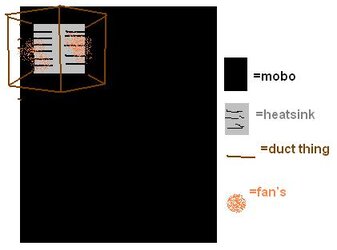

In this first picture you will see this shroud thing I built out of cardboard. I just cut out pieces of cardboard, not entirely square as you can see. I taped these 4 pieces together and probably made an opening of a good 100-150mm above my heat sink. I kind of made a fan adapter, but this is only stage one. At this point, I did not have it on the heat sink. This does not have to be perfect, the pieces I cut out were less than symmetrical