- Joined

- May 23, 2001

- Location

- Asteroid B-612

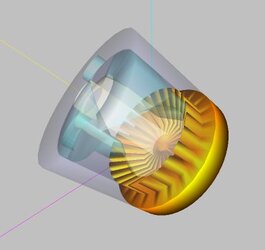

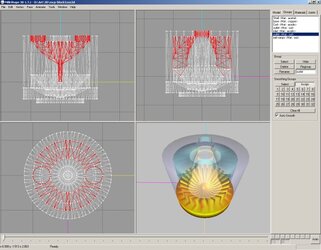

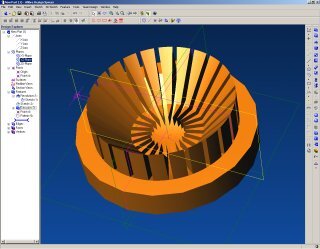

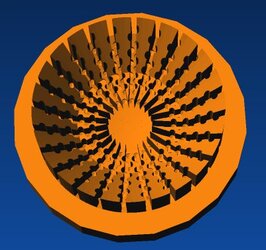

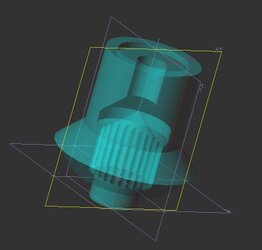

"Nazca" Waterblock

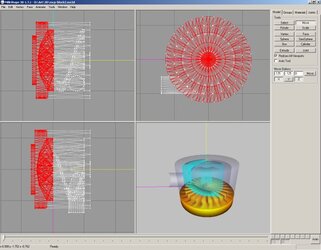

I've been wanting to design a waterblock for a while now. Regardless of whether this amounts to anything or not I'm designing what I can based around what tools I have access to (Manual Mill, Machine Lathe, Drillpress).

Just trying to get feedback on my design. Hit me hard because I've never done this kind of design work before and just wanted to get this concept out in the open. The aim is low restriction, but more turbulance could be added to the fin design by using an alternating drill-hole pattern.

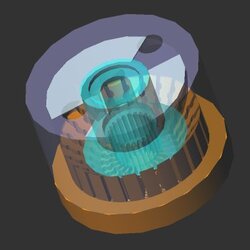

The copper base is 2.5" in diameter with a step on the underside. The acetal top will bolt to the base from the underside. I didn't add the O-Ring to the model but there will be one there.

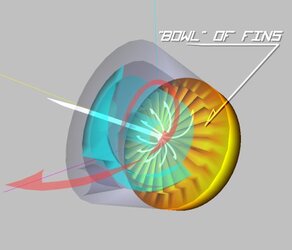

The "bowl" is cut into the base using a slit saw. The barb sizes are 1/2" ID (but could be larger). The inlet feeds directly into the center and then exits around the edges of the fins, then is channeled to the outlet.

I've been wanting to design a waterblock for a while now. Regardless of whether this amounts to anything or not I'm designing what I can based around what tools I have access to (Manual Mill, Machine Lathe, Drillpress).

Just trying to get feedback on my design. Hit me hard because I've never done this kind of design work before and just wanted to get this concept out in the open. The aim is low restriction, but more turbulance could be added to the fin design by using an alternating drill-hole pattern.

The copper base is 2.5" in diameter with a step on the underside. The acetal top will bolt to the base from the underside. I didn't add the O-Ring to the model but there will be one there.

The "bowl" is cut into the base using a slit saw. The barb sizes are 1/2" ID (but could be larger). The inlet feeds directly into the center and then exits around the edges of the fins, then is channeled to the outlet.

Last edited: