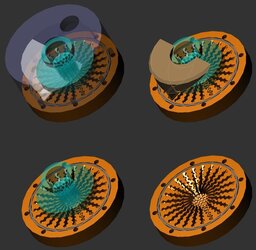

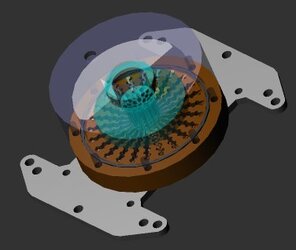

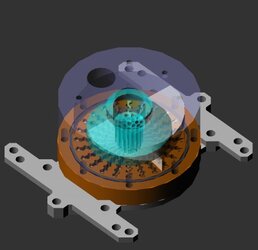

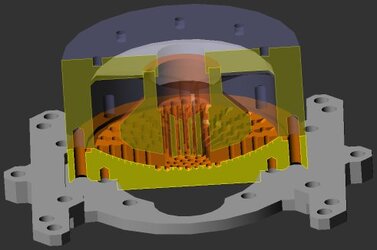

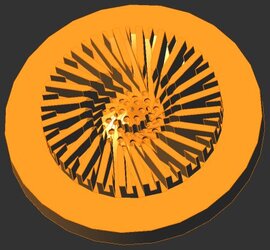

it sounds alot like the polarflo blocks, but with more surface area/turbulence

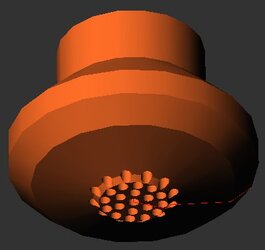

you may want to put a small pillar in the center of the block like polarflo does, and what cathar did with the G4/5 jet cups to create more turbulence

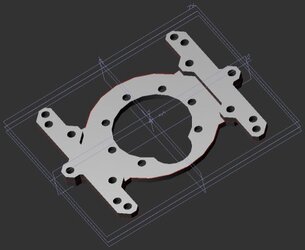

this block also sounds like it could benifit from a 3-barb design in order to equalize the pressure a tad bit better

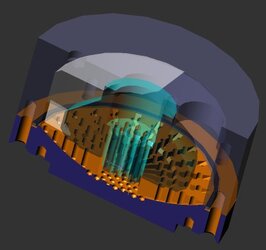

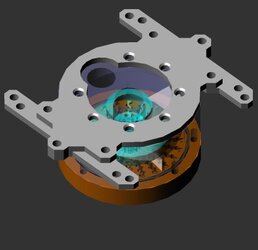

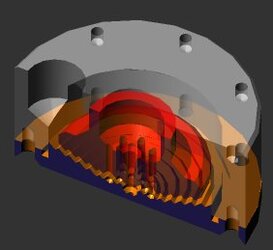

i'm also looking back at the CAD pictures... and it seems as though theres not much in the center of the block to cool directly above the die - its all around the edges, which would probably give you undersireable load temps - maybe reverse the design so that its a pillar in the center, then with the fins tall, and get shorter as you go to the edges of the base

edit: and also have a drill pattern at the center around the pillar and between the first parts of the channels so its somewhat like the DD design posted above

and in the top of the block, create a cone shape to sit on top the f\channels so that water is forced to go through them, and not just skim over the top of them

just my input

-J