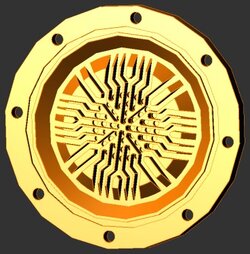

With the jet discs that would give a decent exit velocity (between 2.2 and 6.8 m/s at 1 to 3 gpm flow rate) but probably still be pretty restrictive.

I'd like to see a prototype made.

For the record I also think the 1/8" channels are much better than 1/4" ones (at least with this design).

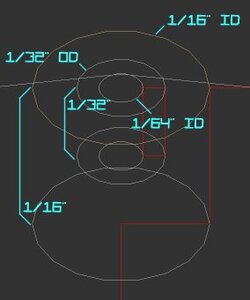

Also if you plan on keeping the outlet at 1/4 NPT it will restrict flow. I would go with two oultets at 1/4 or one at 3/8 if you can.

EDIT: did you get rid of the dimples in the base or can I just not see them from your last pic?

I'd like to see a prototype made.

For the record I also think the 1/8" channels are much better than 1/4" ones (at least with this design).

Also if you plan on keeping the outlet at 1/4 NPT it will restrict flow. I would go with two oultets at 1/4 or one at 3/8 if you can.

EDIT: did you get rid of the dimples in the base or can I just not see them from your last pic?