- Joined

- Aug 17, 2009

- Location

- Virginia,USA

DIY CPU Waterblock (pics inside, 56k warning) and results!Update(8/23)

This was originally posted over at THF, not many interested in WC on that forum lol; probably 4-6 real WCers there). So here we go (PS: 1st post)...........

\\\\\\\\\\\\\\\\\\\\\\\\\

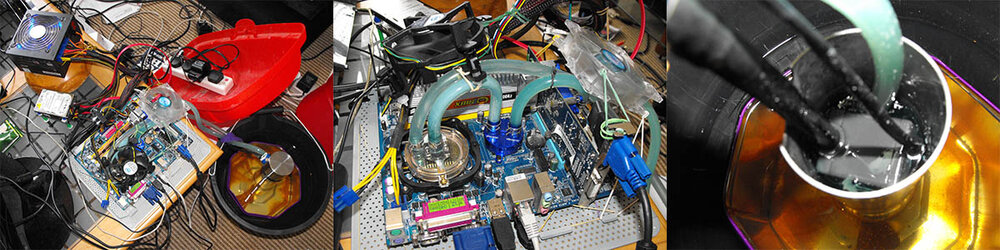

Here are the final results. Block was CNCed (Aluminum 6061); couldn't do on Copper C110 due to cost. The water inlet fitting has some "fittings" inside of it to change/improve turbulent flow. The outlet fitting is untouched.

Leak testing:

Sorry for the mess. Took over my sis's bath room.

A quick rendering of the block:

The rad with a 120mm 110CFM Scythe Slipstream fan:

All assembled on a Celeron D 315 @ 3.6Ghz (CPUZ valid: http://valid.canardpc.com/show_oc.php?id=261994 )

Calculated the ~ Wattage of this thing:

uch: 141W!!!! with OC. No wonder these were called Preshot's :lol:

uch: 141W!!!! with OC. No wonder these were called Preshot's :lol:

The first 10 minutes of P95 small FFT

Temp2 is the CPU temp

After 35 minutes:

Temp2 is CPU.

Note: Voltages shown in SpeedFan are wrong.

Sorry, I had to take pics of the screen with a camera as the test PC was not hooked up to the net (couldn't print screen as the mouse wasn't hooked either ). Heck doesn't even have Win 2k SP4 loaded lol

). Heck doesn't even have Win 2k SP4 loaded lol

Not bad eh? With a Thermaltake P4 SPARK7+ (lapped) the results were 64C under load.

The block was not lapped yet (waiting for 400-1000grit and papers to be back in stock at the local Autozone). CPU was previously lapped. The CPU block is a quite concave so lapping should improve results by ~3-4C.

The Brass fittings are coated with 4+ coatings of clear automotive paint so not much to concern as far as mixed metals goes.

============

What I need help in:

1. What would be the best way to go about making a bracket/bolt in for LGA775?

2. Can I use moded a bolt in bracket from a S1283?

3. I lost my old LGA775 data sheets with all the measurements,guide lines,etc, if you can link me that would be great.

==========

Edit

This was originally posted over at THF, not many interested in WC on that forum lol; probably 4-6 real WCers there). So here we go (PS: 1st post)...........

\\\\\\\\\\\\\\\\\\\\\\\\\

Here are the final results. Block was CNCed (Aluminum 6061); couldn't do on Copper C110 due to cost. The water inlet fitting has some "fittings" inside of it to change/improve turbulent flow. The outlet fitting is untouched.

Leak testing:

Sorry for the mess. Took over my sis's bath room.

A quick rendering of the block:

The rad with a 120mm 110CFM Scythe Slipstream fan:

All assembled on a Celeron D 315 @ 3.6Ghz (CPUZ valid: http://valid.canardpc.com/show_oc.php?id=261994 )

Calculated the ~ Wattage of this thing:

The first 10 minutes of P95 small FFT

Temp2 is the CPU temp

After 35 minutes:

Temp2 is CPU.

Note: Voltages shown in SpeedFan are wrong.

Sorry, I had to take pics of the screen with a camera as the test PC was not hooked up to the net (couldn't print screen as the mouse wasn't hooked either

Not bad eh? With a Thermaltake P4 SPARK7+ (lapped) the results were 64C under load.

The block was not lapped yet (waiting for 400-1000grit and papers to be back in stock at the local Autozone). CPU was previously lapped. The CPU block is a quite concave so lapping should improve results by ~3-4C.

The Brass fittings are coated with 4+ coatings of clear automotive paint so not much to concern as far as mixed metals goes.

============

What I need help in:

1. What would be the best way to go about making a bracket/bolt in for LGA775?

2. Can I use moded a bolt in bracket from a S1283?

3. I lost my old LGA775 data sheets with all the measurements,guide lines,etc, if you can link me that would be great.

==========

Edit

Last edited:

to the forums

to the forums