- Joined

- Dec 11, 2018

I’m sorry but I have never had a bad experience with EKWB . I have used there compression fittings, hardline fittings, blocks, radiators, and reservoirs, and pump tops for years without any issue.

However I have never used this Matt tubing so I can’t comment on that.

Could you please let me know what fitting/tube combination you are using?

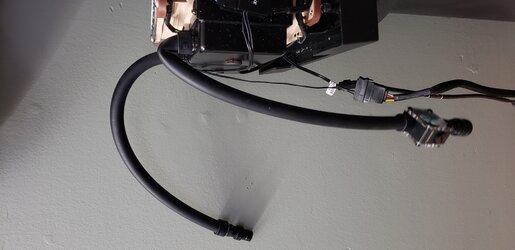

With soft tubing you should have such a tight fit on the barb itself that the tubing won’t leak or come off even without the ring being screwed on.

However I have never used this Matt tubing so I can’t comment on that.

Could you please let me know what fitting/tube combination you are using?

With soft tubing you should have such a tight fit on the barb itself that the tubing won’t leak or come off even without the ring being screwed on.