- Joined

- Apr 22, 2020

- Location

- Caprona

For quite some time, I have been seeking out the "Holy Grail" of objective measurements and formulas that could quantify the Overall Heat Removal capabilities of various cooling solutions. The big question was: Is there such a thing that can be universally applied to any CPU/cooler/system load that will work every time? After sufficient reflection, here is what I came up with...

The amount of heat being removed is, obviously, a function of the CPU load. Therefore, the number that this hypothetical formula will return is just an INSTANTANEOUS SNAPSHOT of the data collected at the moment. To get an overall picture, we need multiple data points. This was the first "realization." We can't rate a Heat Removal Solution with one number. We can say a computer has a 4.0 GHz chip. We can say a triple radiator has a certain interior volume. We can say fans have a max speed. But we can only state the Heat Removal Capacity as a function of a few variables.

So what are the variables?

The wattage output of the CPU

The instantaneous average temperature of the active cores

The ambient temperature of the operating environment

The area of the CPU die itself

Clearly, the more "intense" the program(s) running on the CPU, the more wattage will be exuded. Higher wattage means more heat. This is the first variable.

The second item might seem a little bit murky, since most of our software programs capture the MAX temp on the core (as in HWMonitor) but the instantaneous numbers seem to fly by at amazing speed. What we really need is a "Task Manager" version of the temperatures across each core. More on this later.

If we subtract the ambient temperature of the environment from the core(s) temperature, we have a "working heat reference" of sorts. The bigger the difference, the more heat WITHIN our system as a whole. Smaller is better. Bigger means our Heat Removal Capacity it not that good.

And finally, the heat flux parameter is the area over which this heat is being disseminated. This comes directly from the CPU die itself.

When running a test to get a single Heat Removal Quantifier, the wattage must be captured simultaneously with the average temperature of the active cores. In this respect, it is probably best to either use just one core, or all cores at once. It would be too tedious to cherry pick which core had which temperature as the CPU most often will redistribute the processing load in a computer version of "hot potato."

In the world of thermodynamics, such a concept is referred to as the Overall Heat Transfer Coefficient. But since we are more interested in Heat Removal, I am calling this the "HRQ" rather than that.

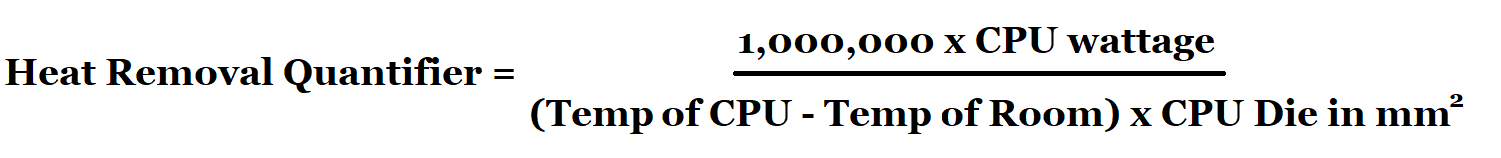

So, here is my formula...

The huge number in the numerator comes from the fact we are dividing by square millimeters instead of square meters, which would match the spec of the thermodynamic definition of the Overall Heat Transfer Coefficient. One millimeter is 1/1000th of a meter, so if we use square milliemeters for the die size in the denominator, we must "square 1000" in the numerator. Dividing by one millionth less is multiplying by a million.

The beauty of this equation is, it accounts for the different temperatures in our operating environment, and still returns a "fair number" to show how hard the heat removal solution is working. In a hotter environment, the CPU temperatures will also be hotter.

One small note: In the Thermodynamics World, we use degrees Kelvin. We can use degrees Celsius here without needing any conversion since we are taking the difference between the two temperatures, and the degrees Celsius climb as fast as degrees Kelvin.

A practical example:

The HRQ for the Corsair H150i = (1000000)x(200 watts)/[(92C - 22 C) x (174 mm squared)] = 16420

HWMonitor displayed 200 watts the instant the core temperatures were 92C in a room temperature of 22C on the i9-9900KS with a die size of 174 square millimeters.

Plug those numbers into my HRQ equation, and you get the number by which you can judge the Corsair H150i's ability to remove heat.

Again, this is ONE DATA POINT and not an exact number everybody will get every single time. But it is a great way to measure your own system!

The 2-fan version of the first iteration of the Thermosyphon scored 17869 just a few days later.

The wattage was 202, CPU average temperatures were 87C, all other factors the same.

So the Thermosyphon kept it 5 degrees cooler even though the CPU was delivering 2 more watts of heat during that test.

Higher numbers = better Heat Removal Capacity.

Feel free to share your HRQ numbers here.

The amount of heat being removed is, obviously, a function of the CPU load. Therefore, the number that this hypothetical formula will return is just an INSTANTANEOUS SNAPSHOT of the data collected at the moment. To get an overall picture, we need multiple data points. This was the first "realization." We can't rate a Heat Removal Solution with one number. We can say a computer has a 4.0 GHz chip. We can say a triple radiator has a certain interior volume. We can say fans have a max speed. But we can only state the Heat Removal Capacity as a function of a few variables.

So what are the variables?

The wattage output of the CPU

The instantaneous average temperature of the active cores

The ambient temperature of the operating environment

The area of the CPU die itself

Clearly, the more "intense" the program(s) running on the CPU, the more wattage will be exuded. Higher wattage means more heat. This is the first variable.

The second item might seem a little bit murky, since most of our software programs capture the MAX temp on the core (as in HWMonitor) but the instantaneous numbers seem to fly by at amazing speed. What we really need is a "Task Manager" version of the temperatures across each core. More on this later.

If we subtract the ambient temperature of the environment from the core(s) temperature, we have a "working heat reference" of sorts. The bigger the difference, the more heat WITHIN our system as a whole. Smaller is better. Bigger means our Heat Removal Capacity it not that good.

And finally, the heat flux parameter is the area over which this heat is being disseminated. This comes directly from the CPU die itself.

When running a test to get a single Heat Removal Quantifier, the wattage must be captured simultaneously with the average temperature of the active cores. In this respect, it is probably best to either use just one core, or all cores at once. It would be too tedious to cherry pick which core had which temperature as the CPU most often will redistribute the processing load in a computer version of "hot potato."

In the world of thermodynamics, such a concept is referred to as the Overall Heat Transfer Coefficient. But since we are more interested in Heat Removal, I am calling this the "HRQ" rather than that.

So, here is my formula...

The huge number in the numerator comes from the fact we are dividing by square millimeters instead of square meters, which would match the spec of the thermodynamic definition of the Overall Heat Transfer Coefficient. One millimeter is 1/1000th of a meter, so if we use square milliemeters for the die size in the denominator, we must "square 1000" in the numerator. Dividing by one millionth less is multiplying by a million.

The beauty of this equation is, it accounts for the different temperatures in our operating environment, and still returns a "fair number" to show how hard the heat removal solution is working. In a hotter environment, the CPU temperatures will also be hotter.

One small note: In the Thermodynamics World, we use degrees Kelvin. We can use degrees Celsius here without needing any conversion since we are taking the difference between the two temperatures, and the degrees Celsius climb as fast as degrees Kelvin.

A practical example:

The HRQ for the Corsair H150i = (1000000)x(200 watts)/[(92C - 22 C) x (174 mm squared)] = 16420

HWMonitor displayed 200 watts the instant the core temperatures were 92C in a room temperature of 22C on the i9-9900KS with a die size of 174 square millimeters.

Plug those numbers into my HRQ equation, and you get the number by which you can judge the Corsair H150i's ability to remove heat.

Again, this is ONE DATA POINT and not an exact number everybody will get every single time. But it is a great way to measure your own system!

The 2-fan version of the first iteration of the Thermosyphon scored 17869 just a few days later.

The wattage was 202, CPU average temperatures were 87C, all other factors the same.

So the Thermosyphon kept it 5 degrees cooler even though the CPU was delivering 2 more watts of heat during that test.

Higher numbers = better Heat Removal Capacity.

Feel free to share your HRQ numbers here.

Last edited: