If you want to be that technical about it, good air coolers are phase change cooling.

Also, those tubes aren't filled with water, they're filled with an alcohol based liquid.

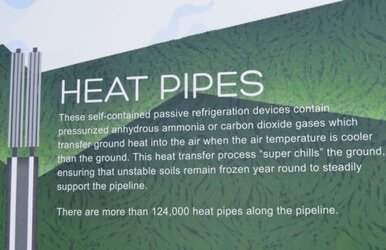

Heat Pipe Materials and Working Fluids

Heat pipes have an envelope, a wick, and a working fluid. Heat pipes are designed for very long term operation with no maintenance, so the heat pipe wall and wick must be compatible with the working fluid. Some material/working fluids pairs that appear to be compatible are not. For example, water in an aluminum envelope will develop large amounts of non-condensable gas over a few hours or days, preventing normal operation of the heat pipe.

Since heat pipes were rediscovered by George Grover in 1963, extensive life tests have been conducted to determine compatible envelope/pairs, some going on for decades. In a heat pipe life test, heat pipes are operated for long periods of time, and monitored for problems such as non-condensable gas generation, material transport, and corrosion.

The most commonly used envelope (and wick)/fluid pairs include:

Copper envelope/Water working fluid for electronics cooling. This is by far the most common type of heat pipe.

Copper or Steel envelope/Refrigerant R134a working fluid for energy recovery in HVAC systems

Aluminum envelope/Ammonia working fluid for Spacecraft Thermal Control

Superalloy envelope/Alkali Metal (Cesium, Potassium, Sodium) working fluid for high temperature heat pipes, most commonly used for calibrating primary temperature measurement devices

Other pairs include stainless steel envelopes with nitrogen, oxygen, neon, hydrogen, or helium working fluids at temperatures below 100 K, copper/methanol heat pipes for electronics cooling when the heat pipe must operate below the water range, aluminum/ethane heat pipes for spacecraft thermal control in environments when ammonia can freeze, and refractory metal envelope/lithium working fluid for high temperature (above 1050 °C) applications.

Read full info here

Heat Pipe