Dray_5820k

New Member

- Joined

- Oct 27, 2017

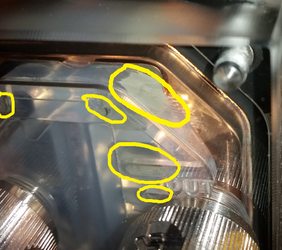

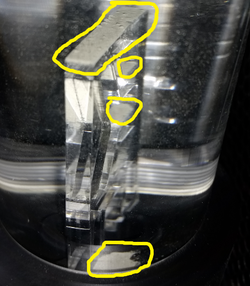

I assembled my first open loop using EKWB's P280 kit. After about four months of use I have noticed a fine light grey silt like sediment building in the reservoir and inside the CPU water block. Prior to installing anything I did flush the radiators (EKWB CE280 and PE240) a couple times each with distilled water. I used two more of EKWB's EK-ACF Fitting 10/13mm (same type that come with the kit) to expand the loop for the PE240. The loop is filled with distilled water and EK's Cryo-Fuel concentrate diluted to the proper concentration. All other loop components are from EK's P280 kit.

Upon close inspection of the CPU block it looks like the sediment is building up where the jet plate opens to the microfins.

My next step is block disassembly and loop flushing. Any suggestions as to why this occurred and how to clean the affected components is greatly appreciated!

Upon close inspection of the CPU block it looks like the sediment is building up where the jet plate opens to the microfins.

My next step is block disassembly and loop flushing. Any suggestions as to why this occurred and how to clean the affected components is greatly appreciated!