-

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

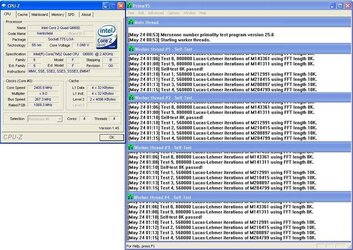

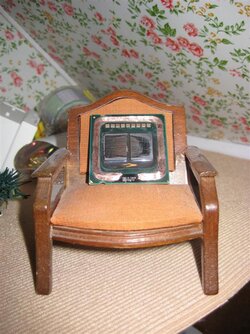

Just removed the IHS from my Q6600

- Thread starter ghost_recon88

- Start date

- Joined

- Nov 28, 2005

- Location

- Dundalk, Maryland

All I can say is your a brave man.

- Joined

- Jul 22, 2002

- Location

- USMC.. OoRah!!

Wow. I think you can buy a lazer temp. sensor for as little as $20. Go for it bro!

- Joined

- Feb 16, 2008

- Location

- East Coast

That would be interesting to check the actual die temp with IR gun with a screenshot of core temp at same time. Would help confirm actual tjmax value.

Several of the transistors on each die function as thermal sensors, and DTS reads the hottest temp as core temp. I guess it is possible to damage them, but like previous poster said, I would not assume that as they are integrated in the chip. And with no tim, I would not be surprised if those were actual temps, despite not seeing much change lowering volts. If not overclocked, you can certainly run stable at those high temps.

Another person who ran without IHS, dual core, also got very high temps until cleaned of crap and put tim on, dont remember how he cleaned it though without damaging it.

Several of the transistors on each die function as thermal sensors, and DTS reads the hottest temp as core temp. I guess it is possible to damage them, but like previous poster said, I would not assume that as they are integrated in the chip. And with no tim, I would not be surprised if those were actual temps, despite not seeing much change lowering volts. If not overclocked, you can certainly run stable at those high temps.

Another person who ran without IHS, dual core, also got very high temps until cleaned of crap and put tim on, dont remember how he cleaned it though without damaging it.

- Joined

- Feb 12, 2005

- Location

- Michigan

- Thread Starter

- #45

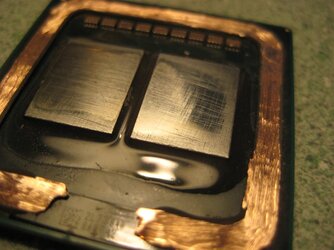

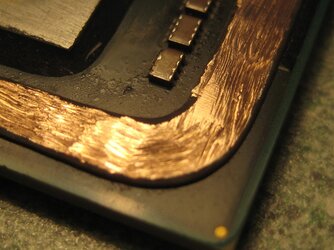

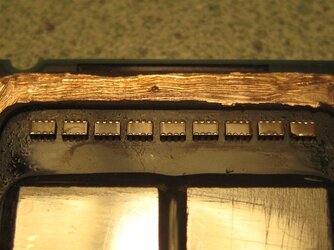

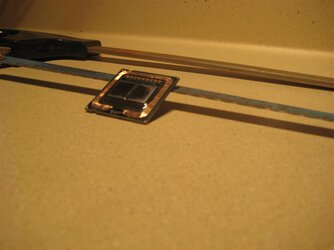

Well the back part of the mobo is getting toasty, so I think those are the actual temps  I've taken off as much of the copper ring around the dies as I can without hitting the PCB, and I've taken off quite a big of the crap on the dies. I don't understand how with the IHS on, as well as the thermaltape in there, the CPU ran cooler then it does with the IHS off, and with the dies making direct contact with the waterblock. And yes, I did put on some AS5.

I've taken off as much of the copper ring around the dies as I can without hitting the PCB, and I've taken off quite a big of the crap on the dies. I don't understand how with the IHS on, as well as the thermaltape in there, the CPU ran cooler then it does with the IHS off, and with the dies making direct contact with the waterblock. And yes, I did put on some AS5.

- Joined

- Feb 16, 2008

- Location

- East Coast

The solder die attach adhesive that intel uses has a thermal conductance much higher than any tim we use. So unless you can get two smooth surfaces like IHS and block to mate with tim, you will end up with higher temps, despite only having one interface (bad interface though), instead of two interfaces (one very high conductance interface of tim1 by intel, and one very smooth interface with tim2 by user).

I think the person that had trouble with higher temp on duo because of solder remnants, used liquid collab pro, as it apparently filled in the spaces of solder remnants better, and got lower temps that way...but that person was concerned of it damaging the die...I know he finally got temps down, but never heard whether the liquid metal tim damaged the die when taken off.

I think that was either on this site or overclock.net...but cant find that set of posts.

I think the person that had trouble with higher temp on duo because of solder remnants, used liquid collab pro, as it apparently filled in the spaces of solder remnants better, and got lower temps that way...but that person was concerned of it damaging the die...I know he finally got temps down, but never heard whether the liquid metal tim damaged the die when taken off.

I think that was either on this site or overclock.net...but cant find that set of posts.

- Joined

- Dec 16, 2007

- Location

- Chicago, IL

Epic thread

- Joined

- Sep 25, 2004

- Location

- Eating thermal paste!@#

Wow awsome thread!

- Joined

- Apr 25, 2007

Looks like I'll belappingbelt sanding the dies then, and yes I've done it before

You, sir, have a set of brass ones. Kudos. I removed the IHS from many an AMD X2, but never had the gumption to give it a go on an new Intel processor.

However, I agree with rge. You're reaching a point of diminishing returns with newer processors; if the stock IHS is seated well, then IHS removal will result in negligible differences in heat dissipation. With early X2 processors, it was apparent that IHS's weren't seated evenly across the die. I believe this issue has been alleviated now, with both Intel and AMD processors.

Still, high five.

However, I agree with rge. You're reaching a point of diminishing returns with newer processors; if the stock IHS is seated well, then IHS removal will result in negligible differences in heat dissipation. With early X2 processors, it was apparent that IHS's weren't seated evenly across the die. I believe this issue has been alleviated now, with both Intel and AMD processors.

Still, high five.

You never answered: How is the thermal paste spread, can you post pics? I really don't think it is making good contact.

Maybe this is an issue with dissipation area?

This is the difficult part. Once the IHS is removed, the TIM layer must be spread thinly and evenly (assuming Arctic Silver TIM product). I used to use a razor blade to do this, and it was a painstaking operation to say the least.

Similar threads

- Replies

- 38

- Views

- 2K

- Replies

- 3

- Views

- 213