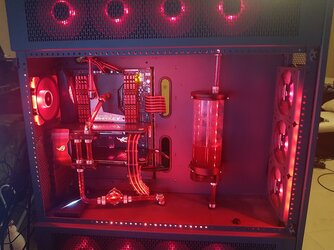

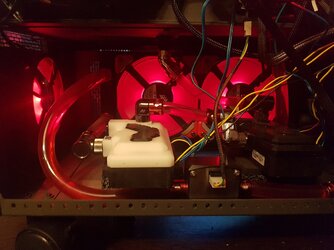

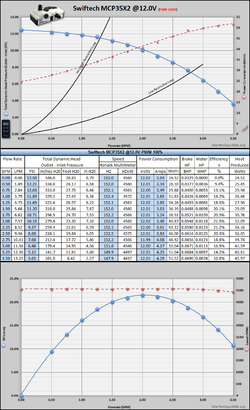

I have a custom loop on my main pc with 2x480 rads 2xgpu blocks and 1 monoblock and with 2x dual swiftech mpc35x pumps and I'm getting less than 0.5 GPM on my loop at 100% on all pumps.

So would I be looking at too many bends or some blockage in one of components ?

Any suggestions are welcome smile.gif

So would I be looking at too many bends or some blockage in one of components ?

Any suggestions are welcome smile.gif