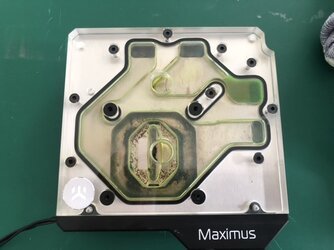

Hi, I have had my system stable and O/C for about 2 months. I have had a small (5mm?) Air bubble in the Gpu block. Yesterday I got a CPU temp shutdown, looked at the innards and it looks like this now and there's a bunch of gunk in the CPU Block, the fluid is cloudy (EK Green fluid) and my CPU temps are high/

I turned off the aura for the photos and turned off O/C.

Is this just a normal bleed issue - what should I do. I intend to drain it and then take the CPU block off an clean it.

When I turn the rig on its side the pump starts to suck air and I know that's bad - how do I get rid of the bubble?

I turned off the aura for the photos and turned off O/C.

Is this just a normal bleed issue - what should I do. I intend to drain it and then take the CPU block off an clean it.

When I turn the rig on its side the pump starts to suck air and I know that's bad - how do I get rid of the bubble?