ok cool, thanks for all the tips guys. Im glad you guys are here. I didn't want to start a new thread, so I will simply ask my next cooling question here as well. First off, an update on what's going on, I got the 360mm radiator painted and actually regret going with the gloss finish, (although it does look much better than it did before.) If I had to do it over again I would probably use something with a less shiny finish.

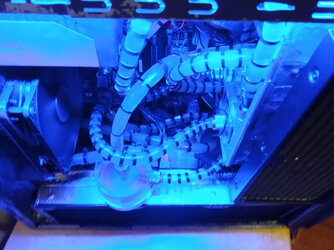

Over the last few days in working on the system I noticed the flow rate is substantially lower than it was a year ago. I suspect I have some things living /and/or obstructions in my loop because as of about 10 months ago I was forced to use straight water in the loop as distilled water was not available at the time. For example, when I first set it up, the flow rate was so strong from the pump (800L/H) it sounded like a mini waterfall (actually added an element of zen to the build lol) as it filled the reservoir. And while I don't have a flow meter, just based on small air bubbles and their movement through the line, I can see my flow rate is about half of what it used to be. The original RPM of the PUMP was about 3600rpm, now it only runs about 3400 maximum rpm. The pump does not make any bad noises and is not cavitating at all, its just very sluggish in actually moving liquid through the loop. No kinks in any of the lines, so I am assuming there may be some gunk in the copper water block and radiator and perhaps in some of the lines as well. I have two right 90* angles which isn't too bad, everything else is clear tubing with no other elbows.

My question is, can I drain the rad and the res (which in total represents about half of the coolant loop volume) and refill it with vinegar and run it through the system for a couple days to kill off any living organisms? I figured I would do it this way so I can free up all the gunk and get the loop spick and span for the upgrades arriving next week so I can start with the best possible performance here.

Speaking of new parts, I am going to get another 120mm radiator, because it's the only one that will fit with the space remaining in the case. Not sure how to post pics directly here so just click the links to see what I got...

1) BXQINLENX 18 Pipe Aluminum Heat Exchanger Radiator (tried to find something copper but this was the best all around deal) - Question, this rad has a very high fin count. How does fin count relate to cooling performance? I am assuming the more fins the more heat dissipation? But then I see some of the alphacool chunky radiators and they have very low fin count, why would they do this?

https://m.media-amazon.com/images/I/61VSMdbpOmL._AC_SL1000_.jpg

https://m.media-amazon.com/images/I/61Y6sVKFT2L._AC_SL1000_.jpg

2) Noctua NF-P12 120mm PWM pump cooling fan

https://m.media-amazon.com/images/I/81ZUUX5VZsL._AC_SL1500_.jpg

https://m.media-amazon.com/images/I/91yQvP00qoL._AC_SL1500_.jpg

3) Wendry PC Water Flow Meter, G1/4 Thread Computer Water Cooling Flow Meter, 6 Impeller 3 Ways Flow Meter Indicator

https://m.media-amazon.com/images/I/51F4uWgtnTL._AC_SL1001_.jpg

https://m.media-amazon.com/images/I/61XnWrPFd2L._AC_SL1001_.jpg

4) EKWB EK-CryoFuel Concentrate PC Coolant, 100mL, Navy Blue

https://m.media-amazon.com/images/I/51OUuoOzpFL._AC_SL1200_.jpg

5) 10 feet new clear tubing

6) all associated plugs and fittings needed to add the new 120mm radiator to my loop.

Im confident the vinegar will help, but should i also hit it with something else, like a couple drops of dish soap or will it just foam up really bad? Also, how long is it safe to leave the vinegar in? I plan on running it for two days at full throttle to flush the loop....

- - - Auto-Merged Double Post - - -

ok cool, thanks for all the tips guys. Im glad you guys are here. I didn't want to start a new thread, so I will simply ask my next cooling question here as well. First off, an update on what's going on, I got the 360mm radiator painted and actually regret going with the gloss finish, (although it does look much better than it did before.) If I had to do it over again I would probably use something with a less shiny finish.

Over the last few days in working on the system I noticed the flow rate is substantially lower than it was a year ago. I suspect I have some things living /and/or obstructions in my loop because as of about 10 months ago I was forced to use straight water in the loop as distilled water was not available at the time. For example, when I first set it up, the flow rate was so strong from the pump (800L/H) it sounded like a mini waterfall (actually added an element of zen to the build lol) as it filled the reservoir. And while I don't have a flow meter, just based on small air bubbles and their movement through the line, I can see my flow rate is about half of what it used to be. The original RPM of the PUMP was about 3600rpm, now it only runs about 3400 maximum rpm. The pump does not make any bad noises and is not cavitating at all, its just very sluggish in actually moving liquid through the loop. No kinks in any of the lines, so I am assuming there may be some gunk in the copper water block and radiator and perhaps in some of the lines as well. I have two right 90* angles which isn't too bad, everything else is clear tubing with no other elbows.

My question is, can I drain the rad and the res (which in total represents about half of the coolant loop volume) and refill it with vinegar and run it through the system for a couple days to kill off any living organisms? I figured I would do it this way so I can free up all the gunk and get the loop spick and span for the upgrades arriving next week so I can start with the best possible performance here.

Speaking of new parts, I am going to get another 120mm radiator, because it's the only one that will fit with the space remaining in the case. Not sure how to post pics directly here so just click the links to see what I got...

1) BXQINLENX 18 Pipe Aluminum Heat Exchanger Radiator (tried to find something copper but this was the best all around deal) - Question, this rad has a very high fin count. How does fin count relate to cooling performance? I am assuming the more fins the more heat dissipation? But then I see some of the alphacool chunky radiators and they have very low fin count, why would they do this?

https://m.media-amazon.com/images/I/61VSMdbpOmL._AC_SL1000_.jpg

https://m.media-amazon.com/images/I/61Y6sVKFT2L._AC_SL1000_.jpg

2) Noctua NF-P12 120mm PWM pump cooling fan

https://m.media-amazon.com/images/I/81ZUUX5VZsL._AC_SL1500_.jpg

https://m.media-amazon.com/images/I/91yQvP00qoL._AC_SL1500_.jpg

3) Wendry PC Water Flow Meter, G1/4 Thread Computer Water Cooling Flow Meter, 6 Impeller 3 Ways Flow Meter Indicator

https://m.media-amazon.com/images/I/51F4uWgtnTL._AC_SL1001_.jpg

https://m.media-amazon.com/images/I/61XnWrPFd2L._AC_SL1001_.jpg

4) EKWB EK-CryoFuel Concentrate PC Coolant, 100mL, Navy Blue

https://m.media-amazon.com/images/I/51OUuoOzpFL._AC_SL1200_.jpg

5) 10 feet new clear tubing

6) all associated plugs and fittings needed to add the new 120mm radiator to my loop.

Im confident the vinegar will help, but should i also hit it with something else, like a couple drops of dish soap or will it just foam up really bad? Also, how long is it safe to leave the vinegar in? I plan on running it for two days at full throttle to flush the loop....