Okay bing, postet it first in another thread here, i tried today to disassemble my beloved TFC1212DE, because its PWM-Wire is missing. I hoped to simply solder a new one on the pcb. Disassembling was no problem but there was no way to me to take the circuit board out of the fan's frame. Now its dead :-(

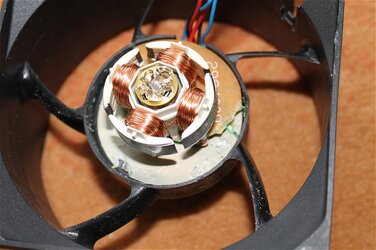

First here comes the power unit of thats fan circuit board. But the wires are attached behind, thats why i tried to remove the board from the fan's frame hub cover. But this

didn' work as expected.

I should have drilled a hole above the soldering spots location.

First here comes the power unit of thats fan circuit board. But the wires are attached behind, thats why i tried to remove the board from the fan's frame hub cover. But this

didn' work as expected.

I should have drilled a hole above the soldering spots location.